Table of Contents

ToggleUnderstanding Overmolding: Applications, Challenges, and Best Practices

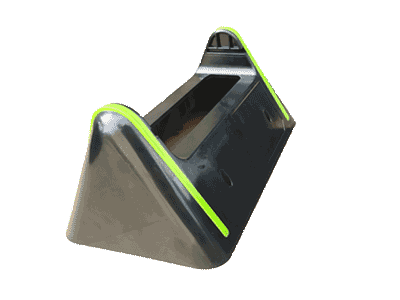

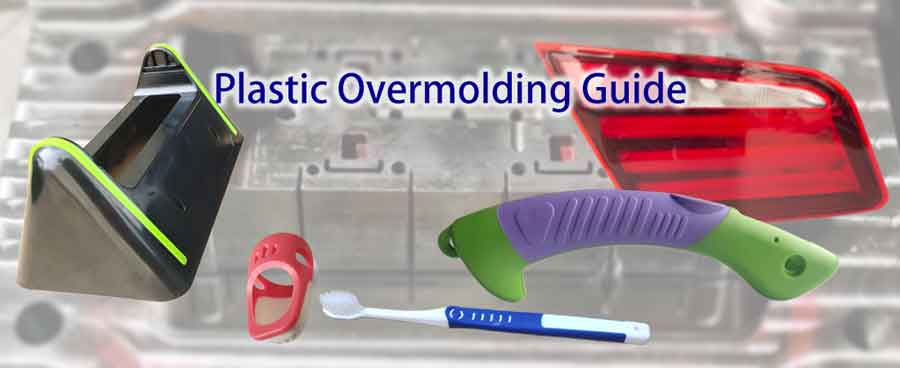

Overmolding, also called plastic overmolding, molding over molding, or injection overmolding, is a crucial injection molding technique widely used in everyday items like toothbrushes, power tool housings, and car light panels. This article will explain overmolding, highlighting its common challenges and essential precautions.

Understanding Overmolding

Overmolding is a process where a substrate, typically a pre-formed plastic part, is placed inside a mold. During the process, molten plastic is injected into the mold cavity, enveloping the substrate in the empty areas. Once cooled, the two materials fuse into a single product.

Although insert molding and 2-shot molding fall under overmolding, they are often referred to separately. In a narrower definition, overmolding specifically involves a plastic substrate manually placed into the mold.

Materials for Overmolding

Commonly, the substrate in overmolding is a hard plastic like PA or PC. The overmolded material, however, can be a flexible plastic such as TPE or TPU, or even another hard material.

It’s crucial that the overmolding material has a melting point equal to or lower than the substrate’s. Using the same material for both is possible, but it requires careful adjustment of the injection molding temperature to prevent the substrate from partially melting.

Multi-shot Overmolding

Overmolding usually involves a single overlay, requiring two injection molds. The final product is a combination of two materials or two color variations of the same material.

There are instances of double overmolding as well, which necessitates three molds, resulting in a product composed of three materials or color variations.

While theoretically, overmolding can be repeated multiple times, such practices are rare in real-world applications and are not the focus of this discussion.

Overmolding vs. Insert Molding

Insert molding typically involves inserting pre-fabricated parts, often made of metals like copper or stainless steel, into an injection mold. These parts can also be made from other materials such as glass, wood, or fiber.

In contrast, overmolding utilizes a previously injection-molded product (the substrate).

From this distinction, it’s evident that insert molding usually requires just one injection mold, whereas overmolding necessitates at least two, and occasionally three, molds.

Overmolding vs. 2-Shot Molding

2-shot molding combines both substrate molding and overmolding in a single injection molding machine. Here, after the substrate is molded, it’s rotated to another station within the same machine for overmolding, eliminating the need to manually transfer the substrate.

This process can even extend to 3-shot molding, particularly in some automotive products, though this is less common.

Manual for overmoldngIn traditional overmolding, the substrate is first injection molded, removed from the mold, and then manually placed into another mold for overmolding.

Advantages for 2-shot moldingThis makes 2-shot molding more efficient and labor-saving. Additionally, since the substrate remains hot during overmolding in 2-shot processes, it often results in a stronger bond between the substrate and overmolding material.

Choosing the Right Option Based on Production VolumeHowever, 2-shot molding requires highly precise molds and thus involves greater initial investment costs. Therefore, the choice between these methods depends on the production volume:

- For large-scale production, 2-shot molding is preferable due to its shorter cycle time, stable quality, and reduced labor requirements.

- For smaller production runs, overmolding is recommended to minimize mold investment costs.

Pros and Cons of Overmolding

Overmolding is a widely used plastic molding process with many advantages but also some limitations. Here are the main pros and cons of overmolding:

Advantages

- Enhanced Comfort and Grip: Adding a soft plastic layer over hard plastic parts improves product comfort and grip, particularly suitable for frequently held components like handles.

- Improved Aesthetics: Overmolding combines different colors and materials to create attractive appearances and textures.

- Increased Durability and Impact Resistance: The soft outer layer absorbs shocks, protecting internal hard components and enhancing overall durability.

- Reduced Assembly Steps: This process integrates multiple parts into one, reducing assembly work later.

- Enhanced Slip Resistance: The soft plastic surface layer improves product slip resistance, ideal for products requiring a non-slip grip.

- Versatility: Different material combinations can give products a variety of physical and chemical properties.

Disadvantages

- Higher Costs: Overmolding requires more complex molds and longer production times compared to traditional single-material injection molding, potentially leading to higher costs.

- Design Constraints: The design must consider the compatibility and adhesion between two materials, which may limit design freedom.

- Material Selection Limitations: Not all materials are suitable for overmolding; a combination that adheres well must be chosen.

- Production Complexity: This process is more complex than single-material injection molding, requiring higher technical skill and more precise production control.

- Recycling Challenges: Products containing multiple materials can be more difficult to recycle and reuse.

In summary, while overmolding technology offers enhanced functionality and aesthetics, it also brings challenges in cost, design, and material selection.

Common Materials and Their Uses in Overmolding

The substrates in over-molding often include materials like PA, PC, ABS/PC, and ABS, while TPE, TPU, TPR, and TPO are common choices for the overmolding layer. This blend of soft and hard plastics represents the most typical form of overmolding.

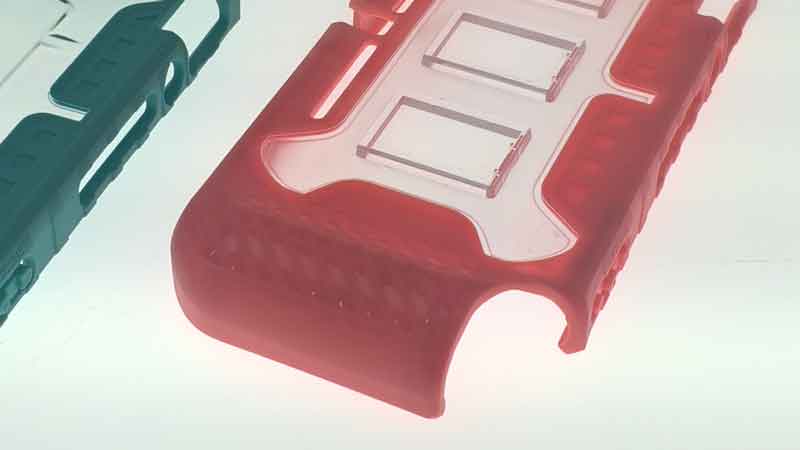

2. Multi-color plastic componentIt’s also possible to use hard plastics for both the substrate and the overmold, usually the same material, often employed in multi-color combinations for aesthetic appeal.

3. Exceeding the limitation of wall thicknessAdditionally, in scenarios where the maximum thickness of an injection-molded product is exceeded, a two-shot injection molding process may be used. This approach ensures each individual molding stays within the maximum allowable thickness.

Theoretically, the possibilities extend beyond these mentioned materials. Essentially, any plastic can be used for over-molding. For specific requirements, please feel free to contact us for more information.

Why Bonding Strength Matters in Overmolding

Bonding strength is a key factor in plastic overmolding. If the bond between the two materials is weak, the overmolded layer may peel off or separate during use. This affects not only the appearance but also the overall feel and functionality of the product. For example, if the rubber grip on a power tool or toothbrush handle comes loose, it can be uncomfortable and frustrating to use.

In products that require sealing, like waterproof enclosures, bonding strength becomes even more critical. This is especially true when the soft overmolded part serves as a button that will be pressed repeatedly. If the bond fails, it can lead to leaks, which may result in product failure.

Levels of Bonding Strength in Overmolding

Bonding strength in overmolding can vary. It’s helpful to understand the different levels, as each one affects product performance differently:

Weak Bonding: The soft material can be peeled off easily by hand, and there is no residue left on the hard plastic. This level is usually not acceptable for most applications.

Moderate Bonding: It takes more effort to tear the soft material off, and a small amount of it remains on the hard surface. This level may be acceptable for non-critical parts.

Strong Bonding: The soft material is almost impossible to remove without damaging the part. If it does tear, a visible layer stays on the hard plastic. However, weaker bonding might still occur in certain areas—such as spots far from the gate (where the material gets cooler) or where the wall is thinner.

Overmolding Adhesion Test

What Affects Bonding Strength in Overmolding

Bonding happens through partial melting.

In overmolding, the soft material is injected in a molten state and makes direct contact with the solid substrate. The heat from the soft material raises the temperature of the substrate surface just enough to soften it—but not melt or deform it. This allows the two materials to fuse slightly at the molecular level, like a mini welding effect at the bonding interface. That’s why heat is so critical: too little, and bonding won’t happen; too much, and the part may warp.

Key Factors That Affect Bonding Strength

1. Type of substrate material matters.

Some plastics bond more easily than others. Generally, substrates with a lower glass transition temperature (Tg) or softening point allow better bonding.

Among common substrate materials, PP (polypropylene) bonds the easiest, followed by ABS and PC. PA (nylon) is harder to bond, and POM (acetal) is the most difficult.

2. Material compatibility improves bonding.

Overmolding materials are often modified to be more compatible with the substrate. This is usually done by adding ingredients that are chemically similar or the same material to the substrate. The closer the match, the stronger the bond.

3. Purity of the soft material affects performance.

Some soft materials contain additives—for example, to reduce hardness—which can weaken the bond.

For instance, TPEs that are designed to bond with nylon generally need a hardness of Shore 60A or higher. If you want a softer feel, plasticizers are added, but that usually leads to reduced bonding strength. Even if no residue is left on the substrate after peeling, a strong bond still requires considerable force to tear apart.

4. Wall thickness influences heat transfer.

Thicker parts retain more heat, which helps soften the bonding surface of the substrate and improves fusion. Thin sections cool down too fast, making strong bonding harder to achieve.

Other Common Issues in Overmolding and Solutions

Short Shot: Even a slight inadequacy in the injection can cause aesthetic defects, leading to product rejection. It’s crucial to design the gate location thoughtfully to prevent short shots. A Design for Manufacturability (DFM) assessment can be used to evaluate the suitability of gate placement, focusing mainly on the required injection pressure.

Flash: Excessive gaps between the mold cavity and the substrate can lead to flash (excess plastic). Moreover, if the gate design is improper, leading to excessive injection pressure (to avoid short shots), it can also result in flash.

Key Design Tips for Overmolded Parts

1. Wall thickness affects heat and bonding.

If the substrate wall is too thin, it’s harder to heat the surface enough for bonding without causing deformation. Thicker walls can absorb more heat on the surface while keeping the inside cooler, reducing the risk of warping.

The same applies to the overmolding material. If it’s too thin, it can’t carry enough heat to properly bond with the substrate. A wall thickness of at least 1.5 mm is generally recommended for good bonding results.

2. Bonding area and distance from stress zones matter.

Larger bonding areas spread out the forces better, reducing the risk of separation under stress. If the bonding surface is too small, more stress is concentrated in one spot, making it easier to peel apart. Also, placing bonding zones farther away from high-flex or deformation areas helps improve durability, as these zones experience less peel force during use.

3. Add grooves, holes, or undercuts to improve grip.

Grooves and holes can increase bonding surface area, while undercuts act like mechanical locks that help prevent the soft material from peeling off. However, these features work better with firmer materials—typically Shore A 60 or higher. For very soft elastomers (like Shore A 45 or lower), the benefit is limited since the material can still flex and pull away more easily.

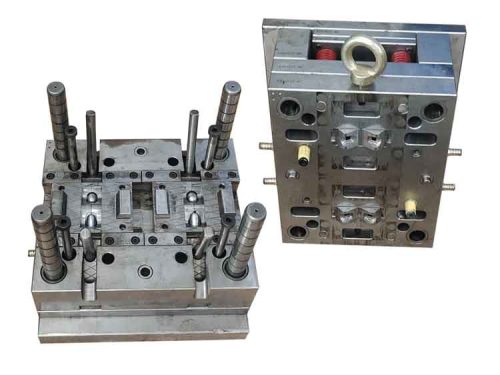

Key Considerations in Making Overmolding Mold

Creating molds for overmolding requires higher precision and a thorough understanding of the overmolding materials. The following are essential aspects to consider in overmolding mold design:

Precision Fit Between Substrate and Mold: The fit between the substrate and the mold cavity in overmolding needs to be very precise. The gap between the substrate and the mold cavity after inserting the substrate should be between 0.01 to 0.03mm. This precision is crucial because materials like TPE, known for their fluidity, can easily cause flash if the gap is too large.

Conversely, a gap that is too small or negative, such as -0.01 to -0.02mm, can create indentations on the substrate surface. Therefore, the mold must be manufactured with high accuracy.

Gate Design in Overmolding: The design of the gates in overmolding molds is highly critical. They must ensure complete filling while maintaining sufficient adhesive force. The key is to ensure that all areas to be overmolded are not too far from the gates. This is to avoid insufficient injection pressure or too low temperatures in those areas, which could affect the quality of the over molding.

Conclusion

In conclusion, overmolding is a versatile and widely used plastic molding technique that enhances product functionality and aesthetics. Despite its complexity, with proper material selection, precise mold design, and attention to key issues like adhesion, short shots, and flash, overmolding offers significant benefits.

Understanding the nuances between overmolding, insert molding, and 2-shot molding is crucial for selecting the right process for specific applications, balancing efficiency, cost, and production volume.