Boyan Manufacturing Solutions Limited

Custom Manufacturing Services Made Easy and Reliable

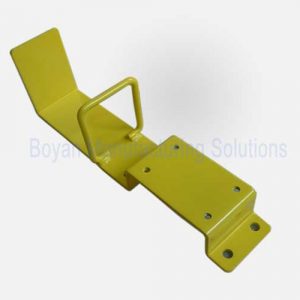

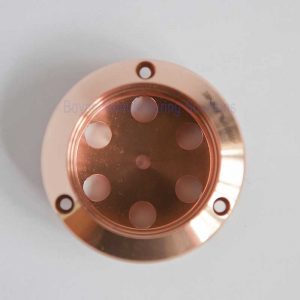

At Boyan, we specialize in providing high-quality custom manufacturing services tailored to meet the unique needs of our clients. Whether you need injection molding, sheet metal fabrication, precision CNC machining, or wire forming, our expert team ensures reliable and cost-effective solutions for all your manufacturing requirements.

Upload your design today to get a fast, free quote and experience the ease and reliability of our custom manufacturing services.

Our Main Capabilities

We provide a wide array of custom manufacturing services, like injection molding, sheet metal fabrication, stamping, CNC machining, wire forming, forging, cold forming, and so forth, which makes us a true one-stop shop for all your manufacturing needs.

♦Mold design ♦Mold making ♦Plastic parts production ♦Rapid Prototyping ♦Reverse engineering ♦Painting and plating

♦Stamping ♦Laser cutting ♦CNC Bending ♦Deep drawing ♦Cold forming ♦TIG/MIG/Laser welding

♦CNC milling (3 and 4 axises) ♦CNC turning ♦Deburring and polishing ♦Highly aesthetic parts ♦100% visual inspection

Offshore custom manufacturing can be less expensive

We aim to keep you fully informed without the need for costly travel through the use of emails, online chat tools, pictures, and videos, which enables us to streamline the project management process, resulting in faster turnaround times and improved overall efficiency.

Our Services

Design and Rapid Prototyping

- Manufacturability check

- Assembly and functionality check

- Tooling and fixture design

- Establish QC inspection criteria

Manufacture

- Accept low and high-volume production orders.

- Detail-minded and quality-oriented.

- First Article inspection, in-process inspection, and before shipment inspection.

Packaging and Shipment

- Packaging and loading plan design

- Ocean shipment or courier delivery arrangement

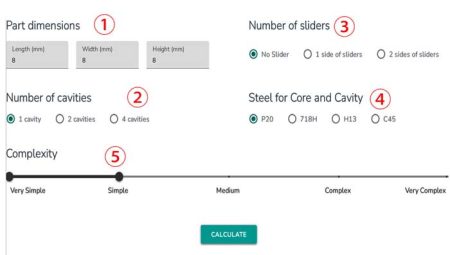

Instant, Transparent Custom Part Quotes

As a custom parts manufacturer, we offer instant quotes with responses typically within 24 hours.

Our commitment to fair and transparent pricing means we keep costs low and clearly outlined.

Each quote undergoes meticulous calculation to ensure precision and accuracy, guaranteeing that you receive the most reliable pricing for your project.

Experience a Seamless Journey: From Quote to Final Product.

Explore the efficiency of our online injection mold cost calculator and receive instant cost estimations!

Who we are

We are a custom manufacturing sourcing company that brings together experienced designers, engineers, and technicians.

When you come to us, we will work with you to find the best manufacturing solutions for your specific task and take care of all details to ensure that the final products meet their specifications.

We will also keep you informed throughout the process so that you can understand how it will be done and how it is going. We believe that understanding takes away worries.

We know that each custom manufacturing job is critical to the success of the entire project, and we analyze every detail of each phase to ensure it can be completed.

Why Choosing Us?

Our unique value proposition

We believe that business ethics and a sense of responsibility are more important than technical and engineering skills for producing quality products in a timely manner. Our dedication to quality and customer satisfaction is what sets us apart.

This is how we ensure our products and service meet the customer’s expectations:

Before production, we will do a technical and capacity assessment of the product to make sure the factory is capable of completing it. We will point out what quality issues may arise and how to avoid them or minimize their impact.

We pay close attention to every detail of our products and keep our customers up-to-date by sending them reports, pictures, and videos. If there are any issues that require further verification, we will send samples to our customers. As a result, our customers rarely receive products with quality issues.

We recommend having video call meetings regularly to make sure the work progress matches our expectations, to check if there are any issues arising, what actions should be taken to solve the problems, so as for us to stay on the same page.

We sign contracts with factories for major processing orders. Production contracts cannot guarantee things going smoothly 100%, but they can at least make the factories more responsible and attentive. We have lawyers who work with us to review and revise contracts. In addition, we mostly use factories that we believe we can trust and have a good relationship with. (We did have a legal case dispute with a factory, click to find out more.)

We understand that confidentiality is important to you. We can assure you that we take confidentiality seriously and will sign a confidentiality agreement (or NDA) to put you at ease. We will also sign a contract with our factory with similar terms. Additionally, we will limit access to information about your product to a “need to know ” level and to who need it.

As a sourcing company, we act as a third party between our customers and factories. If there is a quality issue, we will either refund or replace the defective parts at our expense and hold the factory accountable.

Since we have ongoing orders with the factory it is much easier to settle the dispute.

Testimonials

“I had the pleasure of working with Boyan Manufacturing Solutions, and their deep expertise in plastic injection molding truly shined. They were invaluable in turning a complicated concept into a high-quality final product…

(If you want to hear from our customers about our work, we can share their phone numbers with you. You are welcome to call them.)

Frequently Asked Questions

Custom manufacturing services involve the creation of parts, components, or products that are specifically designed to meet the unique needs of each customer. These services are typically made to order, meaning each item is produced based on the drawings and specifications provided by the client.

Effective custom manufacturing requires a high level of collaboration throughout the entire production process, ensuring that the parts and sub-assemblies align with the performance requirements of the final product.

Whether you need injection molding, sheet metal fabrication, precision CNC machining, or wire forming, custom manufacturing services guarantee that your designs are accurately and reliably brought to life.

At Boyan, we focus on quality, attention to detail, and customer satisfaction.

Unlike many providers, we ensure every step of the process is transparent, offering regular updates with pictures, videos, and reports. Our pre-production evaluation and close collaboration with clients set us apart, ensuring that all projects meet high standards and are delivered on time.

Boyan offers design assistance and rapid prototyping to help bring your ideas to life. We provide manufacturability checks and can design tools and fixtures to meet your needs.

With our expertise in reverse engineering and rapid prototyping, we ensure that your final design is production-ready and optimized for manufacturing.

We accept both low-volume and high-volume production orders. Whether you need a small batch for prototypes or a large production run, Boyan can accommodate your needs. We tailor our services to match the specific requirements of your project, ensuring high-quality output regardless of the order size.

Quality assurance is central to our process. We conduct First Article Inspections, in-process inspections, and pre-shipment inspections to ensure that all parts meet specifications. We also use other quality control systems, ensuring that each part is checked before it reaches you.

Yes, we specialize in manufacturing complex parts with tight tolerances and high precision. From injection molding to CNC machining and sheet metal fabrication, we have the expertise and equipment to handle a wide range of specialized projects, ensuring the best possible results.

We take confidentiality seriously. Boyan ensures that when requested, projects are protected through confidentiality agreements (NDAs) and strict internal controls. We also ensure that our factories abide by similar agreements, limiting access to your product’s details to authorized personnel only.

Yes, we offer full assembly and packaging services as part of our custom manufacturing solutions. Once your parts are manufactured, we can handle the assembly, packaging, and shipment, ensuring that everything is ready for delivery to your specifications.