Boyan Manufacturing Solutions limited

Precision Sheet Metal Fabrication

Expert Service in China

- Low prices

- quality GUARANTEED

- easy communication

- Quick turnaround

For our overseas buyers, Boyan Manufacturing is striving to supply the best sourcing experience for Sheet Metal Fabrication parts and assemblies from China. With our engineering professionals, we are capable of offering from-start-to-finish services like Design For Manufacturing, packaging design, and shipping arrangement.

Our capabilities related to sheet metal fabrication

Fabrication Processes

- Cutting (laser, plasma, water jet)

- Turret punching

- CNC machining (for tight tolerance)

- Bending, forming, deep drawing

- Welding (Tig, Mig, resistance)

- Rivetting

Finishing

- Powder coating

- Wet painting

- Anodizing

- Hot-dip galvanizing

- Plating

Materials available

- Cold-Rolled Steel, Hot-Rolled Steel

- Stainless steel

- Aluminum

- Thickness 0.15-20 mm

Typical Products

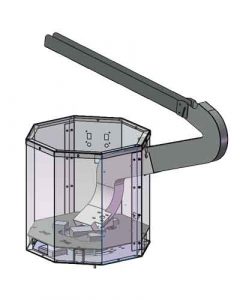

- Weatherproof outdoor enclosure

- Standard server racks

- Custom racks and brackets

- Stamping molds

How do we ensure a quality job?

Design for manufacturing services

Before starting a project, we will evaluate your drawings and check whether your design is ready for shop floor production:

- Bend radius, bend relief, hole diameter, hole to hole distance, hole to edge distance, and more;

- The dimensional and geometrical tolerances. They have to be achievable and yet ensure proper functioning;

- What kind of issues may arise in the manufacturing of this kind of product.

By doing so, we are showing you that all details have been checked, and we have experience in similar products.

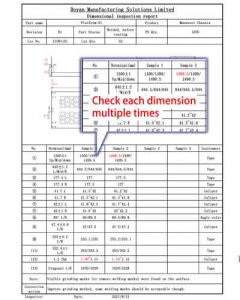

Detailed QC reports

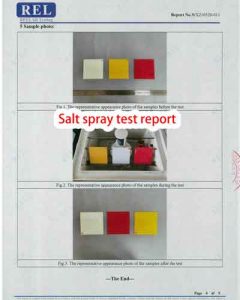

While in production or before shipment, we will send you detailed QC reports, which may include the dimensional report, material certificates, and more (like salt spray test report and so forth).

We will also send you pictures and videos so you can be kept most up-to-date. When you receive the products, they will be just like what you have expected.

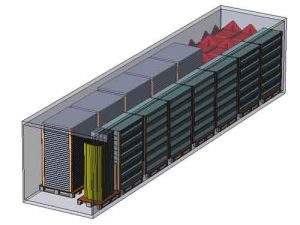

Packaging and loading plan design

- The thin sheet metal parts must be properly packed to avoid possible damage during handling and shipping. Otherwise, they can be easily bent. warped or scratched.

- For full container load, we will design the best loading plan so as to put more products into the container, this will save the shipping cost, and keep things clean and arranged during loading.

Whether you have a complex product to source, or your quality requirements are a bit challenging for average Chinese factories, we are here to get them done, with less spending of money and time.

A factory tour

Automatic Panel Bender

For high production volume, but It has narrower applications due to constraints

Traditional Press Brake

For low-volume productions. It has more flexibility in manufacturing because it is human-operated.

Fully Enclosed Laser Cutting Machine

Maximin thickness: 25 mm CRS

Traditional Laser Cutting Machine

Maximum thickness: 16mm CRS

Welding facitilites

Quality Inspection Equipment

Other pictures

A brief introduction of sheet metal fabrication processes

- Most sheet metal parts are made from flat metal sheets. The first step is to cut the sheets to designed sizes and shapes, these are called the blanks.

- Laser cutting is mostly used nowadays due to its high precision, short turn-around time, and low cost. There are other metal cutting techniques, like plasma cutting, water jet cutting.

- If you want to further lower the cost, shearing and stamping can also be used to produce blanks, but only in large volume productions.

- The leftover material will be wasted. It is critical to choose the right size of the metal sheets, so as to minimize material waste and lower production costs.

- This process is rarely mentioned but it is common in most sheet metal production.

- Most blanks have burrs and slags (created by flame cutting), these need to be removed before the next process.

- Deburring is usually done manually by an electric or pneumatic grinder. There are deburring machines though for large volume productions.

- The flat blanks will then be handled with different forming processes to have desired shapes.

- Bending is mostly used to have straight V-shaped or U-shaped forms. It is conducted on a machine called the brake press.

- The biggest challenge is the correct design of the bending radius. If it is too small, there may be tiny cracks on the bend corners, which may sometimes not be very noticeable but will reduce its strength. A too large radius will probably make the spring-back of the bends uncontrollable.

- Other forming processes utilize stamping molds to form more complex shapes, like indents or louvers.

- When the sheet metal parts are bent, they are sometimes welded to connect the neighboring areas. This is to reach higher rigidity and strength.

- Tig-welding and Mig-welding are mostly used, other options are resistance welding, brazing, and soldering.

- Skills are required to have consistent welding quality and appearance.

- The welds need to be ground and polished to remove the slags and have a better appearance.

- Rivetting are used in some case to serve the same purpose of welding.

- The surface finishing is to add a coating layer, for the purpose of increasing the aesthetic appearance, enhancing corrosion resistance, and protecting the inside metal.

- The pre-treatment is vital for obtaining a good quality of coating. Sometimes you need to send a trained personnel to watch the whole processes on site.

- Before the surface finishing process, careful visual inspection need to be done on the parts, so as to make sure the parts are good quality, because it will be quite difficult to rework the parts after they are coated. You need to do visual inspections as well during and after the process.