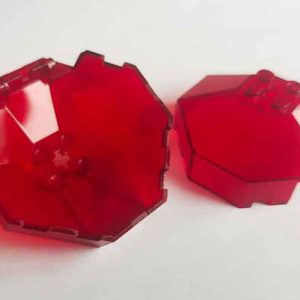

Custom plastic injection mold for LED light bulb socket base

We are capable of manufacturing all kinds of LED light components and their injection molds. Long mold life and high precision are critical for high volume production parts like LED lights, and we must control the weight, wall thickness, etc. of the finished parts very precisely, that way, we can keep the production cost low while maintaining a sustained quality.

Critical quality points

For very high volume production of plastic parts like this light bulb socket bases, it is critical to control the manufacturing costs as low as possible.

In general, these factors have major impacts on the manufacturing costs: production cycle time, parts rejection rate, and precise control of part dimensions.

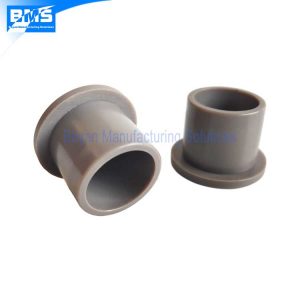

Precise control of wall thickness is of the most importance in this case. The wall thickness has been optimized in the design (not too thick to save material), so the parts need to be made exactly to the drawing specs. There are 8 cavities in this mold, the wall thickness does not only needs to be consistent from side to side, but also from part to part made by different cavities.

This mold is used in a high-speed injection molding machine, this brings a challenge of higher injection speed and molding pressure, then it comes with a higher tendency of uneven wall thickness. With high injection speed, the closer end (to the gate) will be slightly thicker than the far end, so it needs to be offset a little by experience.

Hot runners are used

We use hot runners in the mold. The advantages are obvious: shorter cycle time and reduced material and labor (to remove the molding sprues). This has significantly lowered manufacturing costs.

Mold/part specification

| Cavity material | H13, 718H, S136, 2738, 1.2344, etc. |

| Product material | ABS |

| Cavity numbers | Single or multiple |

| Mold structure | Cold runner, hot runner |

| Mold base | Standard, self-made. |

| Lead time | 30 to 45 days |

Mold cost: $9,000

Mold material: H13

8 cavities

Hot runners