We are capable of manufacturing all kinds of custom-designed plastic gears including spur and helical gears, worm gears, bevel gears, and gear racks of small and large sizes. We have the engineering capabilities of designing gears, choosing the right parameters and materials for gears.

Here we will introduce 3 examples:

1. A worm gear

This is a worm gear that has a pressure angle of 5°.

Gear parameters

| Item | Value | Formula |

| Normal module (mn)/transvese module (mt) | mn=0.906mm / mt=0.92mm | mn=mt*cosβ |

| Teeth number (z) | z=40 | |

| Pressure angle (α) | α=5° | |

| Helix angle (β) | β=10° | |

| addendum coefficient (da*) | da*=0.7 | |

| Reference diameter (d) | d=36.8mm | d=mt*z |

| Tip diameter (da) | da=38.07mm | da=(mt+2da)*z |

| Profile shift coefficient (x) | x=-0.15 |

Information of the part and mold

| Material | POM |

| Dimension of the part | OD 38 * length 33 (mm) |

| Net weight | 13.5 grams |

| Mold cavity number | 1*1 |

| Runner type | Cold runner |

| Mold steel | 718H |

Uniform wall thickness

This plastic gear has a uniform wall and rib thickness, there is no over-thick area, and the ribs are thinner than the main walls. This is very helpful for its dimensional consistency in injection molding.

If you look at the pictures, you may see the wall thickness is not exactly the same, but they are uniformly distributed in the circumferential direction. With proper mold design and injection parameters, they can still maintain good accuracy.

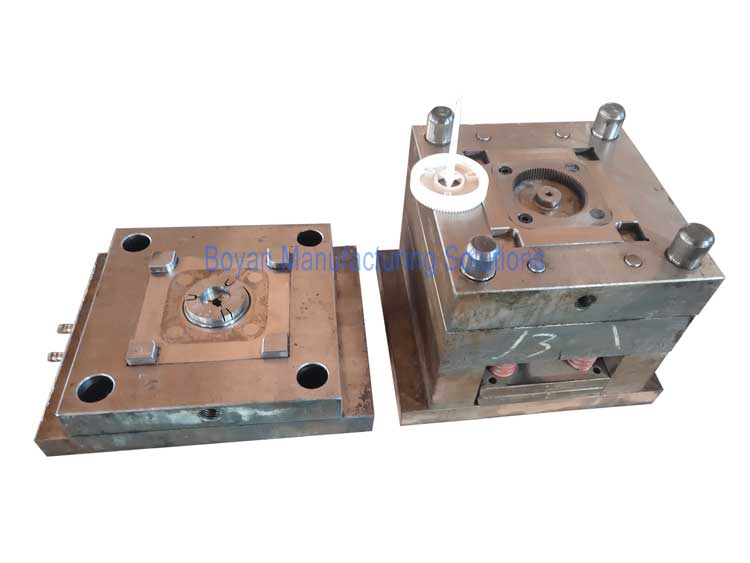

Details of the mold

To ensure the precision of dimensions, this mold has 6 gates. With this design, the roundness of the tip diameter can be held to 0.03mm (for most of the gears produced, the roundness is about 0.01-0.02mm).

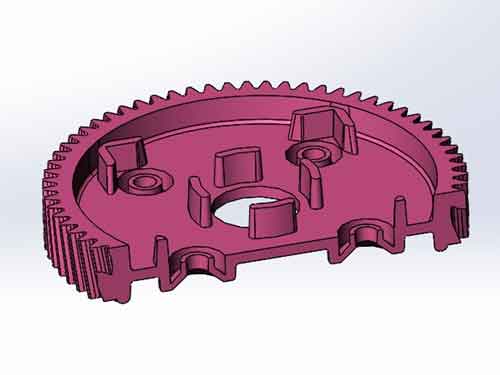

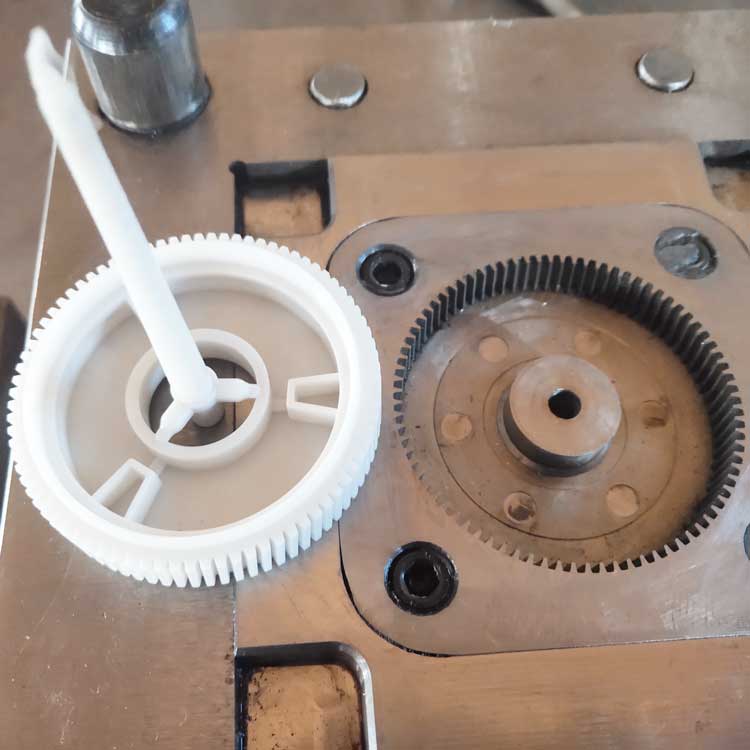

2. A large-sized helical gear

↑Back to top

Usually speaking, the larger gears put higher requirements on accuracy. This is a helical gear with an OD of 95.7mm, which makes the job more demanding.

Gear parameters

| Normal module (mn)/transvese module (mt) | mn=1.4772mm / mt=1.5mm |

| Teeth number (z) | z=62 |

| Pressure angle (α) | α=20° |

| Helix angle (β) | β=15° |

| addendum coefficient (da*) | da*=1 |

| Reference diameter (d) | d=93mm |

| Tip diameter (da) | da=95.7mm |

| Profile shift coefficient (x) | x=0.455 |

Information of the part and mold

| Material | POM |

| Dimension of the part | OD 96 * length 15 (mm) |

| Net weight | 25.5 grams |

| Mold cavity number | 1*1 |

| Runner type | Cold runner |

| Mold steel | 718H |

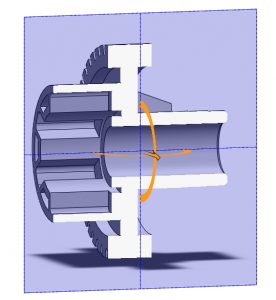

Mold design

This injection mold has 8 gates in order to ensure the precision of the part. Maybe 6 gates will work just fine, but since we used 6 gates on much smaller gears (like the one shown above), we decide to use 8 gates for this one.

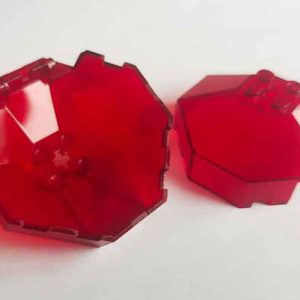

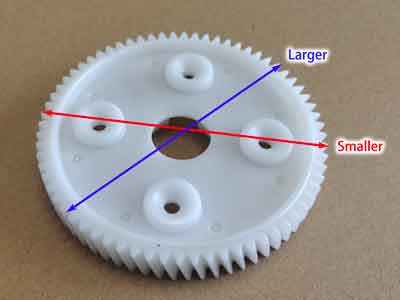

Uneven wall thickness on the web area

In order to meet the functional requirements of use, this gear has 4 bumps on the web and a large wall thickness, resulting in a dimensional unevenness of 0.25-0.30mm in the circumferential direction of the outer diameter. To be more specific, the section above the protrusion is about 0.25 to 0.3mm smaller than the section without the protrusion underneath.

In order to improve the roundness, we hollowed out the back side of the protrusion. However, not much improvement was achieved due to this change.

Tip: it is important to keep uniform wall thickness on the web area. Like said above, the unevenness can be in the radial direction, but not in the circumference direction.

3. A medium-sized helical gear

↑Back to top

pr

pr

Main parameters of the gear

| Normal module (mn)/transvese module (mt) | mn=0.74mm / mt=0.7428mm |

| Teeth number (z) | z=82 |

| Pressure angle (α) | α=20° |

| Helix angle (β) | β=5° |

| Reference diameter (d) | d=60.91mm |

| Tip diameter (da) | da=62.17mm |

| Profile shift coefficient (x) | x=-0.15 |

Tip: Plastic helical gears have many advantages over spur gears, including reduced impact and noise, running more smoothly, more load capacity and longer product life.

Information of the part and mold

| Material | POM |

| Dimension of the part | OD 62 * length 24 (mm) |

| Net weight | 21.6 grams |

| Mold cavity number | 1*1 |

| Runner type | Cold runner |

| Mold steel | 718H |

Details of the mold

This gear has a 3-gate design. This is also commonly used for gears with lower requirements in accuracy.

While in production, the mold temperature is kept at around 140℃, and make the gate a bit widened to ensure the quick fill of material. By doing this, the plastic helical gears are produced with good dimensional stability, and the weld lines are not noticeable.

Other earlier jobs of plastic helical gears

Here are a few pictures: