Sheet metal fabrication quality control

Expert Service in China

- Low prices

- quality GUARANTEED

- easy communication

- Quick turnaround

Our usual quality control operations

At Boyan, we are fully dedicated to ensuring our products meet the specifications. Our usual quality control operations may include:

- First article inspection reports

- In-process inspection reports

- Before shipment inspection reports

- Corrective actions reports

- Pictures and videos that come with these reports

- Material certifications

- Salt spray test reports (for testing corrosion resistance)

- Grid test report (for testing coating adherence)

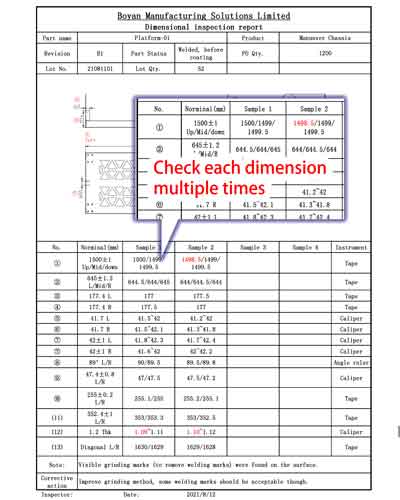

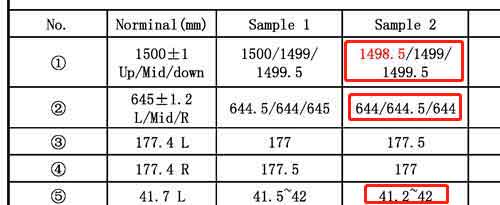

Dimensional reports

Check the dimensions multiple times

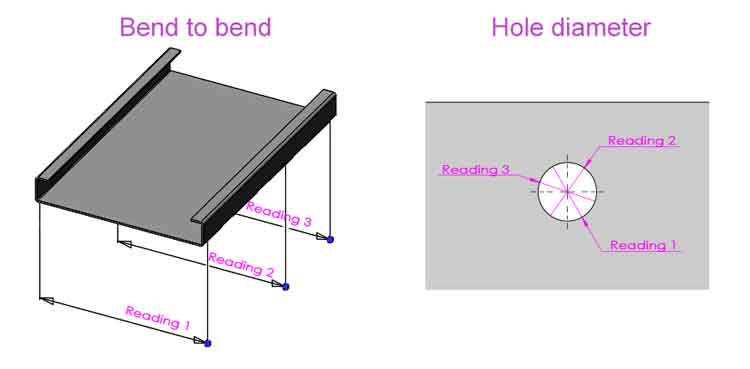

Since for the sheet metal parts, some dimensions may vary a little along its length (or width), especially for those bend to bend dimensions, when we take the measurements, we need to check multiple points to make sure all measurements fall within the tolerances.

Inter-relation of dimensions

For the sheet metal parts, many dimensions are interrelated. In order to check the dimensions more accurately and effectively, we can check the related dimensions.

An example:

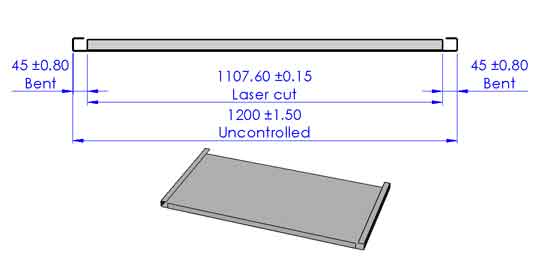

The 1107.60mm is a laser-cut dimension, usually, it can be made within the ±0.15mm tolerance. The 45mm dimensions are obtained by bending, so they are less accurate. The 1200mm is a critical dimension, it needs to be within ±1.50mm.

If we check the 1200mm with a tape, it will be much slower and less accurate.

If we measure the 45mm to be with ±0.60mm,or one side is +0.80mm larger, the other side is +0.40mm larger, the 1200mm should still be within ±1.5mm

Our attention to detail is unparalleled!

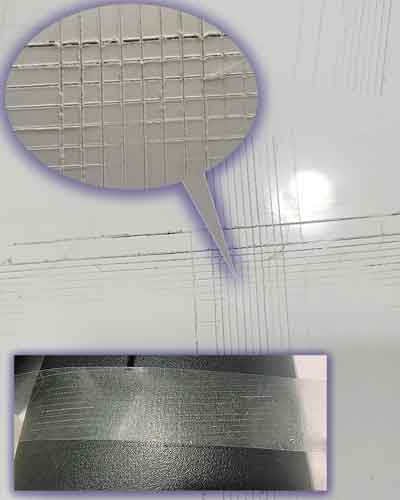

Quality control on the coating processes

Salt spray test report: 3 types-neutral, acetic acid, copper accelerated.

Grid test: for testing the adherence strength of the coating.

These tests are not thorough. When the samples pieces pass these tests, there could still be small areas on some parts that have some issues.

To avoid this, we will perform a visual inspection on the plant during the coating process, to make sure:

- The surface is free of rust;

- The pre-treatment is performed according to the spec, the surface is clean before coating;

- After coating, the coating thickness, surface appearance, etc. meet the criteria.

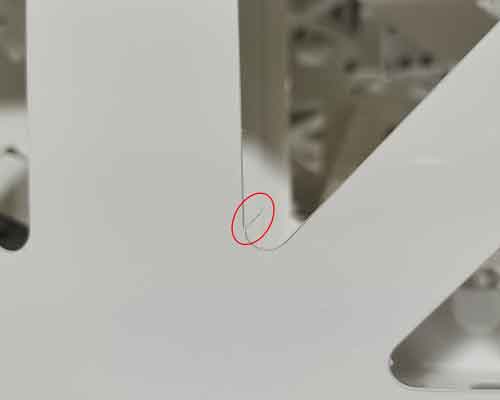

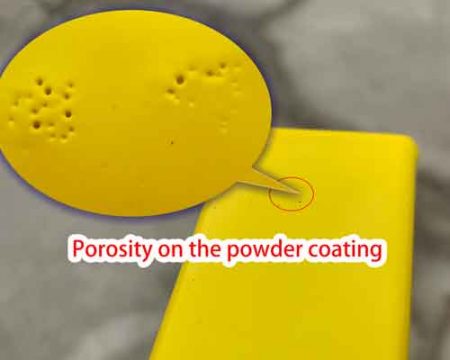

Visual inspection

We will perform visual inspection during all processes of manufacturing to ensure the parts meet the requirements of aesthetic appearance.

We will send you pictures and videos so as to make sure the parts that do not pass the criteria will not be shipped to you.