injection molding - a corner stone of modern manufacturing

Injection molding is a fundamental technique in modern manufacturing, renowned for its exceptional efficiency in mass-producing plastic components. This process essentially involves injecting molten plastic into a mold cavity, where it cools and solidifies, forming the desired part with high efficiency.

While injection molding offers numerous benefits, it also comes with its own set of limitations and challenges. Therefore, comprehending the advantages and disadvantages of injection molding is important.

In this article, we explore the intricate world of injection molding. We will examine its acclaimed strengths, as well as the inherent challenges faced by manufacturers. Through this, we aim to provide a deeper understanding of why injection molding continues to be a crucial process in the production landscape.

Why it is importatnt to understand the pros and cons

Eventually, many products are uniquely suited to injection molding due to their distinct characteristics not found in other manufacturing methods. This article aimed to outline its pros and cons to enable readers to make an informed decision when considering this manufacturing process.

The advantages of plastic injection molding

Injection molding is an extremely efficient and cost-effective method for manufacturing plastic products, with several notable advantages:

1. High Production Efficiency and Low Cost: The cycle time for injection molding typically ranges between 20 to 60 seconds, and for thicker or larger parts, this may be longer. Multi-cavity molds allow for the production of several parts in each cycle. As a result, the production time per item is reduced, thereby lowering the cost per unit.

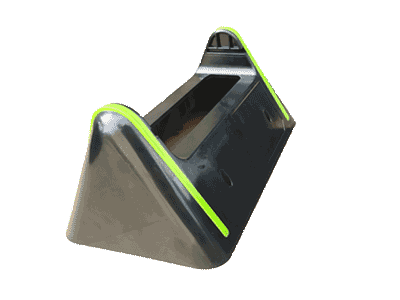

2. Capability to Mold Complex Shapes: Injection molding can easily fabricate parts with complex shapes. The mold cavities can be designed in various intricate forms, and the molten plastic fills these cavities and cools to form the desired shape. Compared to CNC machining, the cost of creating complex-shaped plastic products is much lower.

3. Automated Production: The injection molding production line can be highly automated. Products can be demolded automatically, and the use of robotic arms further reduces manual intervention. However, post-processing such as trimming of excess material and visual inspection is still required.

4. High Dimensional Consistency: Injection molded products maintain high repeatability and consistency within the tolerance range. Although the precision is slightly less compared to CNC machining, it usually meets the requirements for most applications.

5. Diverse Material and Color Options: Plastics are polymers, classified into categories like standard plastics, engineering plastics, and special plastics. Modern plastics can match or even exceed certain metals in terms of strength, heat resistance, and corrosion resistance.

6. Rich and Detailed Surface Textures: The surface of injection molds can achieve a mirror finish. Moreover, modern injection molding techniques can create a variety of surface textures, such as leather or sanded finishes. 3D laser texturing technology allows for even more intricate and delicate patterns, like stitched lines on a leather-textured surface.

7. High Material Utilization and Recyclability: In injection molding, material utilization is high, with most of the material forming the part, except for the sprue and runners in the molding system. Compared to CNC machining and stamping processes, waste generation in injection molding is relatively low. In theory, most injection molding materials can be recycled for reuse, although practical limitations may apply.

The disadvantages of plastic injection molding

Injection molding, a key method for producing plastic products, offers many advantages but also comes with several significant drawbacks:

High Initial Investment, Not Ideal for Small Batches: The cost of molds for standard plastic products typically ranges from $1,000 to $5,000. For larger or export-standard molds, prices can soar to several hundred thousand dollars. Compared to 3D printing and CNC machining, injection molding becomes cost-effective only when producing 100 to 150 pieces or more. Aluminum injection molds may be considered to save 20-30% of the cost, but their shorter lifespan needs to be weighed against the savings.

Long Mold Production Cycle: Manufacturing an injection mold usually takes 30 to 45 days. Adding the time for inspection and shipping samples, the initial waiting period can be lengthy. Further delays can occur if modifications are needed after producing the T0 sample. It’s important to factor in this preparatory phase when planning an injection molding project.

Quality Risks in Products: Unexpected molding defects such as warping, gate blush, and stress marks can occur during injection molding. When partnering with a new factory, an incomplete assessment of their capabilities might lead to quality issues later.

Difficulty in Modifying Designs: Altering a product design after the mold is complete often requires remaking the mold core or even the entire mold. In lucky cases, it might be possible to make modifications by welding (additive manufacturing) on the mold core. The rule of thumb is that adding material to the original geometry (i.e., removing material from the mold) is feasible to a certain extent, but excessive changes are not practical.

Design Limitations: Ideal injection-molded products should have thin, uniformly thick walls. The design process must consider factors like draft angles and undercuts, which might require the use of sliders and lifters, necessitating extensive experience in injection molding design.

Material Limitations: Despite significant advancements in modified and special plastics, they still fall short of metals like aluminum and steel in terms of strength, rigidity, and wear resistance.

Recycling and Environmental Concerns: In theory, plastics can be reused, but recycling faces many challenges. Sorting and categorizing recycled materials require substantial manpower and resources. Currently, only a small percentage of plastics are recycled. Painted or plated plastic products, as well as those with embedded metal parts, cannot be reused until the metal is manually removed. Repeatedly injection-molded plastics significantly lose their performance.