When is Low-Volume Injection Molding Required?

The general understanding is that injection molding is best suited for large-scale manufacturing due to the significant upfront investment in mold costs. In mass production, costs per unit decrease substantially when distributed across each item. Nevertheless, there are scenarios where low-volume injection molding becomes a necessity. This can be observed during the product development testing phase or for products with limited market demand, yet a requirement to fulfill the specific needs of certain customer segments persists.

Why Choose Injection Molding Over Other Processes

While there are alternative methods like 3D printing and CNC machining for low-volume production, injection molding maintains its relevance in specific cases. Our experience highlights several compelling reasons for its continued use:

In essence, while 3D printing and CNC machining have their merits, injection molding stands out when it comes to cost-effectiveness, intricate designs, superior mechanical properties, and dimensional accuracy, making it the process of choice for various low-volume production scenarios.

1. Cost Efficiency: Injection molding becomes cost-effective when the production volume surpasses 50 or 100 units. In comparison, CNC processing or 3D printing tends to become more expensive as quantities increase, leading to a widening cost gap as production scales up.

2. Complex Shapes: Injection molding excels in producing intricate details and complex shapes that may be cost-prohibitive or impossible to achieve through CNC machining methods.

3. Mechanical Properties: The mechanical properties and service life of commonly used plastics significantly outperform 3D printed materials. For instance, reinforced nylon used in 3D printing may only exhibit 70% of the strength of conventional reinforced nylon, falling short of desired standards. Additionally, 3D-printed materials can deform under stress and tend to have a relatively shorter service life.

4. Dimensional Accuracy: Injection molding consistently delivers superior dimensional accuracy compared to 3D printing, making it the preferred choice for applications where precise measurements are crucial.

What Constitutes low volume / Small Batch Injection Molding?

Defining “small batch” injection molding can be somewhat nuanced and depends on the complexity of the product. In general terms, small batch injection molding can be characterized as follows:

For relatively simple products, an order quantity of less than 100 pieces, or an order amount below 200-300 US dollars, can be considered small batch. For more intricate or complex products, the minimum order quantity and order amount may increase accordingly. The definition of a “small batch” in injection molding can vary based on the specific requirements of the project and the product’s intricacy.

Why Low-Volume Injection Molding Presents Challenges?

While it may seem that producing a small quantity of items is merely a matter of cost, the reality is more complex. Low-volume injection molding comes with its own set of challenges, distinct from larger production runs:

1. Industry Norms: Many injection molding facilities are accustomed to handling large, high-volume orders. Their work areas, quality inspection procedures, and standard processes are optimized for these conditions and may not readily adapt to the unique requirements of low-volume runs.

2. Labor Intensiveness: Low-volume orders often require a disproportionate amount of labor compared to large batch orders. These smaller orders may involve several workers and, when factoring in material costs and other expenses, sometimes yield profits of less than $100. For businesses, it’s akin to the effort required to hire a plumber for a short, inconsequential task.

3. Limited Interest: Even if customers are willing to pay extra for small orders, many manufacturers might not find it economically appealing. Low-volume orders are sporadic, and they would rather focus on larger-scale projects that don’t demand additional effort or resources.

However, it’s worth noting that some specialized facilities are more open to accommodating low-volume orders. These manufacturers are typically experienced in trial molding and small batch processing and are more inclined to take on smaller, one-off orders due to their expertise in this niche.

Other Factors Influencing Minimum Order Quantities

While we’ve discussed the minimum order quantity, several additional factors can affect it, including:

1. Material Purity: Products demanding higher material purity, such as transparent or light-colored items with stringent surface quality standards, often necessitate larger order quantities due to the specialized and refined materials used.

2. Customized Inserts: When customized inserts are integral to the product design, the sizes of these inserts are typically relatively small. Consequently, the minimum order quantity for such products tends to be higher, often ranging from 5,000 to 10,000 units or more.

3. Painting and Electroplating: Products requiring painting or electroplating can be challenging to fulfill even if the order quantity reaches 5,000 units or the order amount hits 5,000-10,000 US dollars. This can be attributed to the limited number of facilities specializing in these processes, especially in regions with stringent environmental protection policies. Furthermore, such facilities may be selective with orders, occasionally refusing smaller quantity requests or exhibiting less cooperation due to the effort involved.

Note: In China, for instance, strict enforcement of environmental protection policies has significantly reduced the number of facilities offering painting, electroplating, and similar processing services, leaving them overwhelmed with orders. Their selectivity in accepting orders primarily depends on the alignment between the workload and order value. This is particularly relevant for plastic products that require post-processing to meet quality standards.

How to Reduce Costs in Low-Volume Injection Molding

Minimizing costs in low-volume injection molding can be achieved through several strategies:

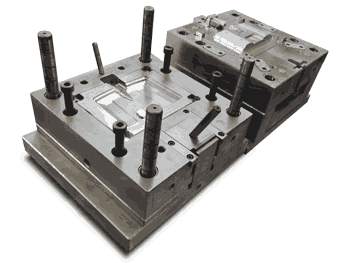

1. Reduce Cavity Number: This is a straightforward approach since for small batch plastic products, the primary focus is on lowering mold expenses, considering that production costs are relatively small.

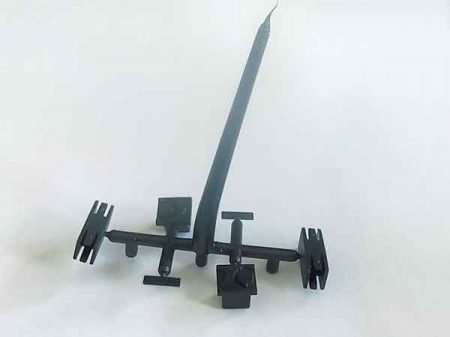

2. Utilize Family Molds: Family molds involve consolidating different parts into a single mold, reducing the overall number of molds needed. However, it’s essential to be aware of their limitations, such as the necessity for similar parts to be grouped in a family mold, and quantity constraints to ensure optimal quality across all parts.

3. Simplify Mold Designs: Consider simplifying mold designs. For instance, you can replace intricate thread unscrewing mechanisms with manual ones, or convert certain slide mechanisms to manual operation, thus reducing manufacturing complexity and costs.

4. Increase Order Quantity: If the demand for a product, though small, is predictable, it may be prudent to raise the order quantity for each production run. This reduces the frequency of purchases and can lead to cost savings in the long term.

By implementing these cost-saving strategies, you can make low-volume injection molding more economically viable while maintaining product quality and meeting specific project requirements.

Delivery Times for low-volume / Small Batch Orders

It’s a common scenario that smaller batch orders often come with extended lead times, although there are nuances to consider:

Initial Orders: Typically, the first order is not subject to longer lead times as it is often integrated into the mold calculation cycle. The final stage of mold production includes trial production. The discussion here pertains to subsequent orders.

Production Scheduling: In many injection molding facilities, the injection molding machines are in high demand and need to be carefully scheduled to accommodate various orders. The underlying economic principle is straightforward, idle machines can potentially be sold or used for larger, more profitable orders in the future.. In such situations, larger orders and established customers often take precedence, enjoying higher priority. Smaller orders, on the other hand, receive lower priority and sometimes have to fit into production schedules, resulting in waiting times.

Typical Waiting Period: This waiting period for small batch orders can vary but generally falls within the range of 1 to 3 weeks. It’s important to acknowledge and plan for these lead times when considering low-volume injection molding projects.

Understanding these dynamics helps manage expectations and ensures that your project aligns with the production timelines and priorities of the injection molding facility.

The Customer’s Role in Ensuring Timely Delivery

Set Reasonable Expectations

Small orders often lack the strong commercial incentives found in larger ones. Their success hinges more on contractual obligations and ethical commitments. In this context, customers should adopt a collaborative, team-player mindset rather than assuming a superior position. A sincere and cooperative attitude can facilitate smoother progress in the production process.

Extend Delivery Timeframes Whenever Possible

As discussed earlier, small orders may entail longer production cycles. To mitigate this, it’s advisable to place orders as early as feasible, allowing for an extended processing cycle. This additional time enables thorough inventory checks and more precise planning for delivery schedules.

Maintain Regular Communication

Consistent communication with the factory is crucial. Customers should engage in regular discussions, whether through email or phone, to update the factory on project progress and emphasize the importance of on-time delivery. This continuous communication reinforces the significance of the order while also conveying the rationale and necessity behind the set delivery date. In most cases, this approach encourages better cooperation from the manufacturing facility.

For customers dealing with small orders, it’s vital to abandon the “set and forget” mentality. Instead, they should be prepared to invest time and effort continuously to ensure that orders are fulfilled promptly and efficiently.