Table of Contents

ToggleWhat Are Injection Molding Surface Finishes

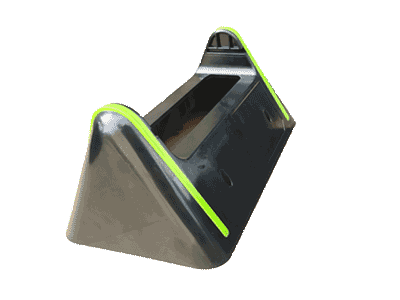

Injection molding surface finishes refers to specific grade of roughnesses, textures or patterns created on the surface of a mold, encompassing not only surface roughness but also various design patterns.

Surface roughness affects the tactile feel and visual quality of the finished product, while design patterns offer unique visual effects. These textures can imitate natural materials like wood grain and leather, or abstract geometric shapes, and are widely used in industries like automotive, electronics, and consumer goods.

By adjusting the mold surface texture, product utility and aesthetics can be enhanced, and minor imperfections from the manufacturing process can be concealed.

The Role of Injection Molding Surface Finishes

Mold surface textures in injection molding not only enhance the practicality of products but also their aesthetic appeal.

- First, different surface textures can imitate various materials such as metal, wood, or leather, thereby enriching the product’s texture and visual appeal. For instance, a smooth, polished surface can impart a high-end, refined appearance.

- Moreover, appropriate roughness can improve grip and enhance the adhesion of coatings or overmolding materials to the product surface, ensuring durability.

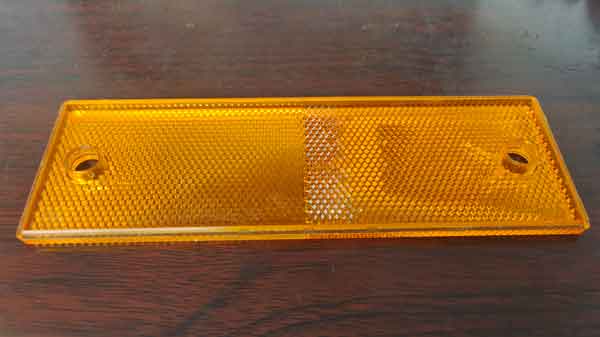

- For transparent components, polished surfaces can also enhance optical properties, like clear light projection and visibility. In optical applications, such as lenses, the quality of polishing is particularly crucial, directly affecting the performance of optical devices.

In these ways, mold surface texture technology becomes an integral part of product design, enhancing functionality, aesthetics, and performance, thereby boosting the market competitiveness of the final product.

Processing Methods for surface finishing in injection molds

Mold surface finishes can be created using a variety of processing methods, each with its unique characteristics and suitable applications. Here are some common processing methods:

Textures Formed by Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) uses the high temperatures generated by electrical sparks to melt and evaporate material, forming a sand-like texture on the mold surface. The coarseness of the surface texture can be adjusted by varying the discharge rate.

This method can produce a range of fine textures, similar to sandblasting effects but more durable.

Manual Polishing

Manual polishing involves using abrasive materials and tools to manually smooth the mold surface. This process is particularly effective for removing scratches and achieving a desired level of smoothness.

The method is especially suitable for molds requiring high gloss levels, like those needing highly reflective surfaces. The initial step usually involves using a whetstone to eliminate machining marks. This is followed by the use of progressively finer grades of sandpaper to enhance the surface’s smoothness.

For achieving mirror-like finishes, wool wheels combined with diamond paste are employed. Polishing is a meticulous process, demanding significant patience and precision, and is often conducted in dust-free workshops.

Moreover, manual polishing serves as a foundational step for further mold surface treatments like sandblasting and etching. In certain high-precision plastic products, T0 samples require polished surfaces for thorough inspection of surface quality. Only after this initial step are additional surface textures applied, underlining the extensive application of polishing in mold processing.

Chemical Etching

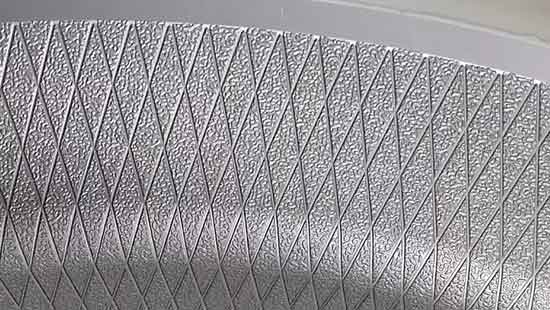

Chemical etching involves creating a unique texture on the mold surface through a chemical reaction. This method is ideal for producing fine, regular textures required in precise mold surface processing.

The process starts with preparing the mold surface, which includes flawlessly polishing it. Then, a photo-etching technique is used to create a pattern, followed by preparing a silk screen. Resistant inks are then applied to protect certain areas, and the mold undergoes chemical etching, often using a strong acid. The ink-covered areas remain unetched, while the exposed parts are etched away, forming the desired pattern.

Sandblasting

Sandblasting involves propelling sand particles at high speed to impact and roughen the mold surface. This straightforward and rapid method is especially suited for treating large areas on a mold.

For sandblasting, materials like silicon carbide and glass beads are commonly used. Their coarseness is measured in mesh sizes, typically ranging from around 10 to several hundred, with 80 to 200 mesh being the most frequent choice.

However, surfaces treated with sandblasting tend to smooth out and lose their texture over time. Compared to textures created by other methods, sandblasted surfaces have a shorter lifespan and thus require regular reprocessing to maintain their desired effect.

Electroplating

Electroplating involves depositing a thin metal film onto the surface of a mold, enhancing its wear resistance and corrosion protection, and also adding a decorative effect.

Chrome plating is a common choice, significantly increasing surface hardness (to above HRC65) and improving corrosion resistance, resulting in a smoother surface.

Another option is titanium plating, which offers its own unique set of benefits.

Electroforming

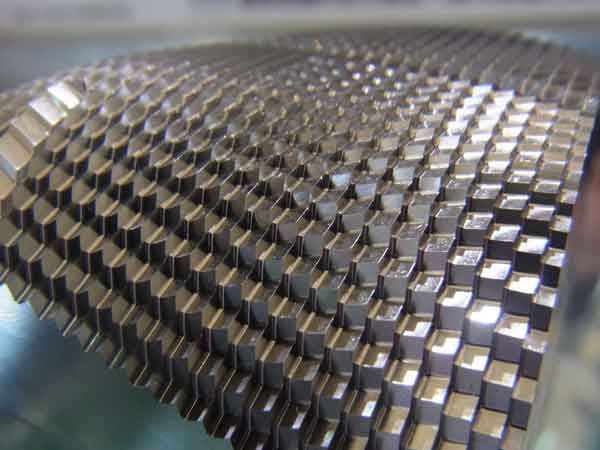

Electroforming involves depositing a metal layer onto a mold, which is then peeled off to create metal components with complex shapes and fine textures.

This technology is ideal for producing high-precision and high-gloss mold surfaces. It’s particularly suitable for patterns with greater surface depth. However, due to its high cost, electroforming is not as widely used as some other techniques.

5-Axis Laser Engraving

5-axis laser engraving employs high-precision laser devices to etch intricate and detailed patterns on mold surfaces. Capable of three-dimensional processing, this technology is particularly suitable for high-end and delicate mold fabrication.

2 Examples of 5-axis surface texturing

In theory, in conjunction with 3D pattern design, 5-axis laser engraving can create any desired texture shape with precise dimensional control, surpassing other methods in this regard. However, due to the high cost of the equipment, the processing fees are also significant, which limits its widespread adoption.

The table below provides a quick comparison of six different processing methods.

| Process | EDM | Manual Polishing | Sand-blasting | Electro-plating | Electro-forming | 5-Axis Laser Engraving |

|---|---|---|---|---|---|---|

| Price | Moderate | Low to high | Low | High | Very High | Very High |

| Popularity | High | High | Moderate | High | Low | Low |

Current Common Injection Mold Surface Finishes Standards and Norms

In plastic manufacturing and mold design, mold surface finishes standards are vital. The three most accepted and utilized standards are SPI (Society of Plastics Industry), VDI 3400 (Standing for Verein Deutscher Ingenieure, meaning the German Engineering Association in English), and MT (Mold-Tech).

While many factories have their proprietary texture plates, these three are globally recognized. SPI is prevalent in the U.S., VDI 3400 in Europe, and MT’s versatility and flexibility make it widely adopted worldwide.

The SPI Standard

The SPI (Society of Plastics Industry) standard, established by the American plastics industry, guides the surface treatment of plastic injection molds. It categorizes mold surface textures into four main classes—A, B, C, D—each further divided into three levels, making a total of 12 types of surface treatments.

- Class A (A-1, A-2, A-3) denotes polished surfaces for high gloss, suitable for products requiring smooth, mirror-like appearances.

- Class B (B-1, B-2, B-3) involves brushed surfaces for medium gloss and fine textures, ideal for visually appealing products not needing high gloss.

- Class C (C-1, C-2, C-3) is also brushed but coarser than Class B, used for products needing medium roughness, often to enhance grip or conceal manufacturing flaws.

- Class D (D-1, D-2, D-3), the roughest, typically involves sand-textured surfaces, for products requiring enhanced tactile feel or specific visual effects.

Overall, SPI standards focus more on the degree of polish rather than pattern styles, playing a crucial role in manufacturing by aiding manufacturers in selecting suitable surface treatments based on product requirements.

Overview of SPI standard for polishing

| SPI (new) | Description | Ra in µm (DIN) | Comments |

|---|---|---|---|

| A-1 | Diamond buff grade 3 | 0 – 0.025 | For mirror or optical finishes. Most time-consuming. Steel grade important to results. |

| A-2 | Diamond buff grade 6 | 0.025 – 0.05 | |

| A-3 | Diamond buff grade 15 | 0.05 – 0.076 | |

| B-1 | 600 grit paper | 0.05 – 0.076 | Removes all tool and machining marks. Provides good mold release. Light reflecting finish on molded part, some sheen. |

| B-2 | 400 grit paper | 0.10 – 0.127 | |

| B-3 | 320 grit paper | 0.23 – 0.25 | |

| C-1 | 600 stone | 0.25 – 0.30 | Removes all tool and machining marks. Provides good mold release. Mute finish on molded part, no sheen. |

| C-2 | 400 stone | 0.64 – 0.71 | |

| C-3 | 320 stone | 0.97 – 1.07 | |

| D-1 | Dry blast glass bead 11, 200 distance at 0.7 Mpa; 5 sec | 0.25 – 0.30 | For decorative finishes. Often used for diecast and thermoset cooling. Helps hide shrink marks and other imperfections. Dull, non reflecting finish on molded or cast part. |

| D-2 | Dry blast 240 oxide, 125 distance at 0.7 Mpa; 5 sec | 0.66 – 0.81 | |

| D-3 | Dry blast 240 oxide, 150 distance at 0.7 Mpa; 5 sec | 4.83 – 5.84 |

The VDI 3400 Standard

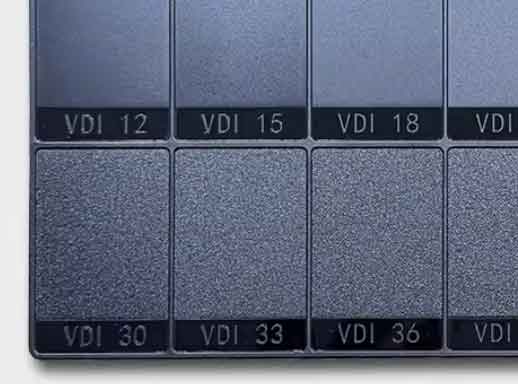

The VDI 3400 standard, established by the German Engineering Association (Verein Deutscher Ingenieure), defines the texture processing of mold surfaces. It encompasses 46 different texture grades, ranging from VDI 3400 #0 (very fine) to #45 (very coarse).

The surface textures in VDI 3400 are primarily created through the electrical discharge machining (EDM) process, ideal for producing fine textures. However, for larger surfaces, to avoid uneven or excessively rough textures, supplementary techniques like polishing chemical etching and sandblasting are employed. This comprehensive approach makes the VDI 3400 standard versatile for various design needs and applications.

The table below shows the relationship between common SPI grades and the corresponding surface roughness (in Ra value).

| Grade | Ra (µm) | Grade | Ra (µm) |

|---|---|---|---|

| 0 | 0.10 | 24 | 1.60 |

| 3 | 0.15 | 27 | 2.20 |

| 6 | 0.20 | 30 | 3.20 |

| 9 | 0.30 | 33 | 4.50 |

| 12 | 0.40 | 36 | 6.30 |

| 15 | 0.55 | 39 | 9.00 |

| 18 | 0.80 | 42 | 12.50 |

| 21 | 1.1 | 45 | 18.00 |

The MT Standard

Differing from the previously mentioned standards, the MT (Mold-Tech) standard is developed and promoted by a company, rather than an industry association.

It not only defines surface roughness but also encompasses a wide variety of pattern designs, such as leather grain, wood grain, and geometric shapes. Owing to its diverse range of patterns, the MT standard includes thousands of different specifications, offering immense flexibility and creative scope in product design.

Most Common MT Grades

| Grade | Depth(in.) | Minimum Draft Angle |

|---|---|---|

| MT 11000 | 0.0004 | 1.0° |

| MT 11010 | 0.0010 | 1.5° |

| MT 11020 | 0.0015 | 2.5° |

| MT 11030 | 0.0020 | 3.0° |

| MT 11040 | 0.0030 | 4.5° |

| MT 11050 | 0.0045 | 6.5° |

| MT 11060 | 0.0030 | 4.5° |

Conclusion

For most users, the most common types of mold surface fnishes include polished, sand-textured, and brushed finishes. Thus, when selecting mold surface treatments, users typically need to choose one of these three types and determine the required roughness level.

From this perspective, the application of the SPI and VDI standards is relatively straightforward and user-friendly, as they provide clear guidelines that help users easily choose the appropriate surface finishing type and roughness level.

If your requirements are more specific or unique, then you should opt for the solutions provided by MT, or seek out relevant mold factories or design firms, as they will offer more personalized surface texture design solutions.