High-Quality Custom Injection Moulding Services for the UK, Made in China

We have extensive experience in successfully collaborating with multiple UK clients, particularly in the production of custom injection-moulded plastic components and tooling. Our proven track record of close cooperation enables us to provide tailored solutions and consistently deliver high-quality results, ensuring client satisfaction in every project.

design review and optimization

mold fabrication

injection molding production

Real Cost Saving Compared to UK Mould Makers

Mold Price: 1/5–1/8 of UK

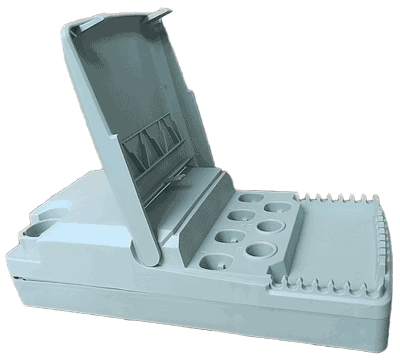

The cost of moulds is approximately 1:5~8 when comparing China to the UK. Here’s a real-world example: For this simple plastic enclosure, our mould price is £960, while a UK-based mould maker quoted £5,800.

Even when factoring in shipping costs, the savings are clear and significant. This is why many UK companies, especially startups, choose to source injection moulds from China, achieving remarkable cost reductions.

Verify our low prices with our online mould price calculator

We also strive to keep our prices competitive among our Chinese peers. To estimate our pricing, you can try our self-service online mould price calculator to calculate mould costs, or contact us for a manually calculated price and compare it with the results from the calculator.

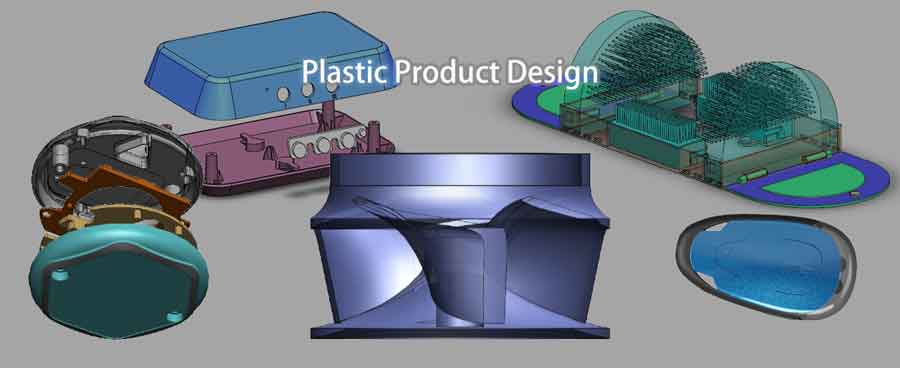

from design to reality

Even if you’re not an expert in injection moulding, we will use our expertise and knowledge to bridge the gap, optimising your design to make it more suitable for the injection moulding process.

Comprehensive Design Review

We meticulously assess product designs to ensure they are fully optimised for injection moulding. Suggestions for improvements and necessary revisions are provided, which are then sent to the client for approval, helping to save valuable time.

In-Depth Content Analysis

Our review includes detailed evaluations of factors such as draft angles, wall thickness, aesthetic requirements, dimensional tolerances, and the selection of suitable materials.

Collaborative Mould Design

Next, we proceed to the mould design phase, working closely with the client to finalise critical details such as gate type, gate location, and parting lines.

Final Product Delivery

Once the design is approved, you can leave the rest to us. We will ensure the delivery of high-quality products to the client.

nt.

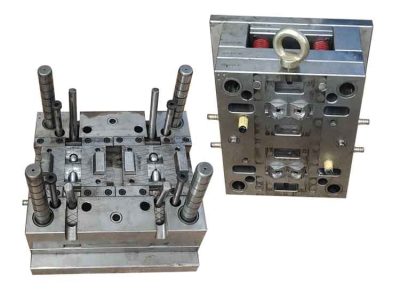

Attention to key details

We approach every project with a deep understanding of the product, recognizing that attention to key details is essential for achieving high-quality results.

Appearance and Premium Feel

The focus on the product’s appearance and premium feel is crucial in our process.

Precision in Dimensions

Ensuring dimensional accuracy is vital to guarantee proper functioning and alignment between parts after assembly.

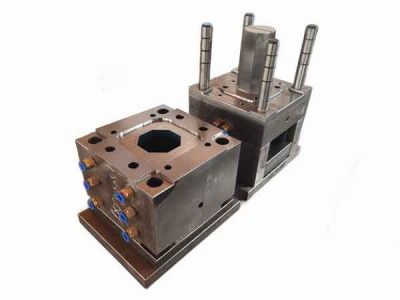

High Precision

Located in a region known for its developed mold processing industry, our factory benefits from a wealth of resources for superior mould manufacturing and injection moulding.

Precision Machinery

Our precision machining equipment ensures the necessary accuracy, which is crucial for maintaining the quality of our moulds.

High-Accuracy Molds

For moulds with stringent requirements, we can achieve precision of up to +/-0.01mm, allowing the moulds to be assembled and used with minimal manual adjustments.

Express delivery offers the convenience of direct delivery to your doorstep without requiring you to manage customs clearance, as the courier takes care of it on your behalf. Additionally, a combined model of sea, rail, or truck freight with express delivery is available, providing a more cost-effective alternative to traditional sea freight.

| Shipping Method | Delivery Time | Cost (US$/kg) |

|---|---|---|

| Premium Express | 3-5 days | 9-11 |

| Flat Rate Express | 7-8 days | 8-9 |

| Sea Freight + Express | 55-60 days | 3.5 – 4 |

| Railway Freight + Express | 40-45 days | 4 – 4.5 |

| Truck Freight + Express | 35-38 days | 4.5 – 5 |

Note: The above rates apply to shipments weighing over 21 kg. For goods that are bulky but light in weight, charges are based on volume, calculated as: volume (cubic centimetres) / 5000.

For large shipment volumes, traditional sea freight remains the most cost-effective option.

Traditional air freight has costs similar to express delivery, which is why it is less commonly used.

Both sea and air freight require customs clearance, which is typically managed by engaging a customs broker. However, we can also arrange door-to-door delivery for your convenience.

Comprehensive Logistic Options

There are several options for shipping goods from China the UK, categorized into express delivery (courner service) and traditional sea or air freight.

Convenient and Effective Communication

Delivering Key Details

Inspecting products relies not only on expertise and experience but also on good photography. This allows us to send you detailed and accurate images, ensuring you receive a more thorough understanding of the product than an in-person inspection might provide.

Collaborative Approach

We take the time to fully understand your needs and ideas, addressing issues promptly to meet your quality requirements. Our goal is to ensure your complete satisfaction with our products.

Contact Us Today

At Boyan Manufacturing Solutions, we assist you at every stage of product development, from design and rapid prototyping, mould making, plastic parts production to various post-processing steps such as printing, painting, and secondary machining.

Our commitment to quality, effective communication, and customer satisfaction ensures that turning your idea into reality is a seamless process. Contact us today!

Frequently Asked Questions

Answer: Firstly, the variety of transportation options, including air freight, rail, truck, and sea shipping, provides more choices to reduce costs compared to countries like the US or Australia. Additionally, the UK imposes relatively low tariffs, or in some cases none at all, on goods imported from China.

The lead time for injection moulding projects depends on the complexity, precision, and size of the mould. Typically, the production cycle for an injection mould takes between 25 to 40 days. The initial samples produced from the mould are referred to as T0 samples.

After inspecting the T0 samples, mould modifications may be required. These adjustments could include design changes or corrections to meet the specified dimensions. Once modifications are complete, the next set of samples, known as T1 samples, are produced. This process can take an additional 15 to 25 days, plus extra time for shipping and sample inspection, bringing the total to approximately 30 days.

In summary, the entire process, from project initiation to mould completion, typically takes around 2 to 3 months. On rare occasions, a second round of modifications may be needed, although this is uncommon.

Efficient communication throughout the sample inspection and problem-solving stages is critical. Without it, the overall timeline may be extended further.

We do not impose restrictions on the Minimum Order Quantity (MOQ). For certain products, the quantity can be as low as 100 pieces. While we hope this will lead to more orders in the future, it is absolutely fine if it does not.

However, please be aware that smaller orders may have longer lead times. This is because such orders are usually processed during the gaps in other production schedules, particularly when specific production conditions or additional post-processing are required.

Certainly! We offer a comprehensive range of secondary operations and finishing services, including surface treatments such as painting, plating, screen printing, pad printing, and laser etching. In addition, we provide welding, machining, and assembly services, among others, to cater to the diverse needs of our clients and ensure their projects are completed to the highest standards.

Certainly. If requested, we can promptly ship the mould to you, although such situations are rare. Typically, once customers have their moulds manufactured and stored at our facility for production, it is uncommon for them to retrieve the moulds midway through the process.