It is not easy to find a high-quality anodized aluminum extrusions manufacturer. As a sourcing company, we have tried several different manufacturers until we have found one that we feel comfortable with. In this post, we will be glad to share our knowledge and experience in this sector. If you want us to help you purchase the anodized aluminum extrusions or finished parts made out of them, or you want to contact the manufacturer directly, please contact us.

Table of contents:

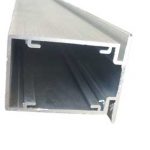

What are anodized aluminum extrusions

They are usually cut to 6 meters long and anodized. The anodizing can be different colors, but clear anodize is the most common, black anodize comes the next. There are other color options, but they need to meet a higher MOQ, say, like 15 to 20 tons.

The anodized film for clear anodizing is usually 0.005 to 0.008 mm thick. A thicker anodized film can provide better protection, but the appearance will become more dull and yellowish, which makes it less appealing.

For black anodize, the coating thickness is usually 0.009 to 0.012 mm.

The surface will usually be sand blasted, this helps to cover the light mold marks and other minor imperfections, it also has a pleasing appearance, and it is a required finish of many products.

The advantages of using anodized aluminum extrusions

A great advantage is the lowered cost. Imagine that you want to produce some anodized aluminum parts out of the extrusions, there are 2 ways you can do it, anodize before or after the fabrication of parts:

1. Anodize the aluminum extrusion before machining.

Pros:

- Lower costs. It is cheaper to anodize the entire pieces than to anodize many separate pieces.

- You avoid the rejection of the part due to anodizing defects, this saves you a lot of time and money.

Cons:

- The cut section is exposed without anodic file (bare metal). However, in many cases this is acceptable.

- You cannot remedy the surface defects (scratches, dents) caused in the secondly processes (machining, loading and unloading and so forth).

2. Anodize the parts after they have been machined from raw extrusions.

Pros:

- The complete part is anodized with the protective coating, except the rack marks (they are usually small spots).

- Some minor surface flaws can be remedied before anodizing, but only for those very minor flaws.

Cons:

- The parts with anodizing defects will all be rejected. Many of them are not remediable.

Conclusion: As you can see, using anodized aluminum extrusions to produce parts (option 1 shown above) can save costs and reduce quality rejections, so this is the recommended option over the other one (anodize the individual parts).

Usual quality requirements for anodized aluminum

Anodizing is a complex electrochemical process that consists of 3 steps: pre-chemical treatment, anodizing and sealing. Each step has multiple parameters (like temperature, concentration and time) to be controlled precisely. More or less, the anodizing defects will come with the finished parts, many of the anodizing defects are non-remediable, meaning the whole pieces of the parts with anodizing defects will be rejected.

Generally, the quality requirements for aluminum anodizing can be classified into 2 groups:

- That the anodic oxide film is made to expected quality (like the thickness, uniformity) so it will provide the desired protection, hardness, etc.

- That the appearance of the parts is consistent and pleasing, the glossiness and color is as desired, and they are free of mechanical damages (like scratches, dents).

It is a bit complicated to explain the quality requirements for aluminum anodizing in full detail, but you will see the most common anodizing defects for extrusions below.

Many anodizing defects can be detected by visual inspection. The larger the parts are, the more likely they will have some defects here or there, simply because they are larger. This puts a higher requirement for the long aluminum extrusions because they are so long (thus larger in the area and heavier in weight).

High quality requirements for aluminum extrusions is quite challenging

In many cases, the visual requirements for aluminum extrusions are set lower than other smaller parts.

Like aluminum ladders or outdoor furniture, some small defects are considered acceptable.

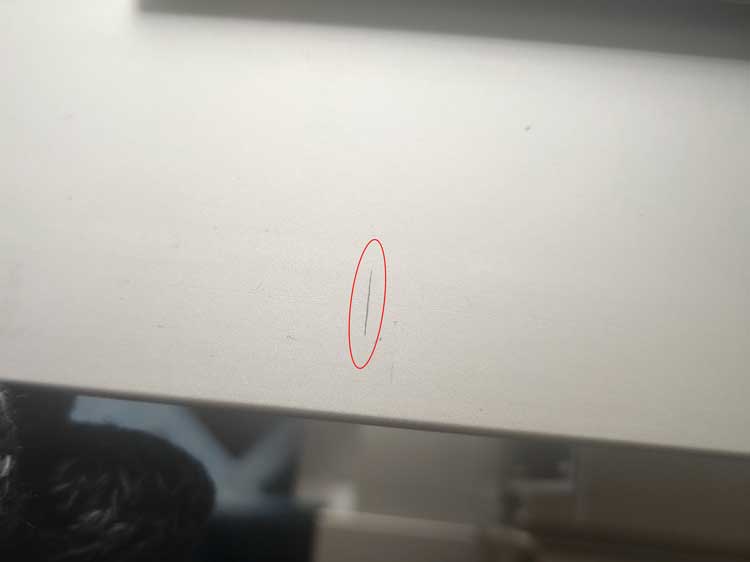

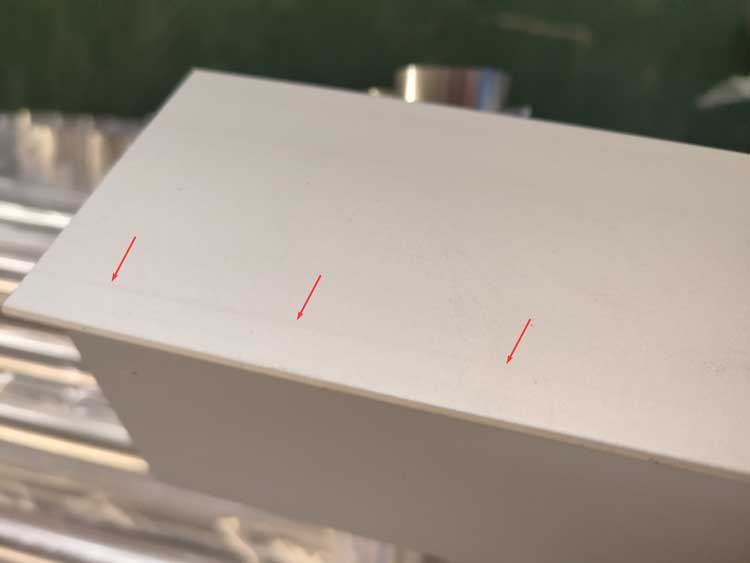

However, if you have a higher quality requirements, we can also supply 6 meters long anodized aluminum extrusions with almost no flaws, only this kind of flaw like pin-point should be accepted.

In every 1 meter long profile, 3 spots of smaller than 0.3 mm2 are acceptable.

Spots of smaller than 0.3 mm2

Common anodizing defects for aluminum extrusions

- Surface scratches and dents (mechanical damages). The bigger the surface area is, the heavier the parts are, the more likely the parts will have this kind of flaws.

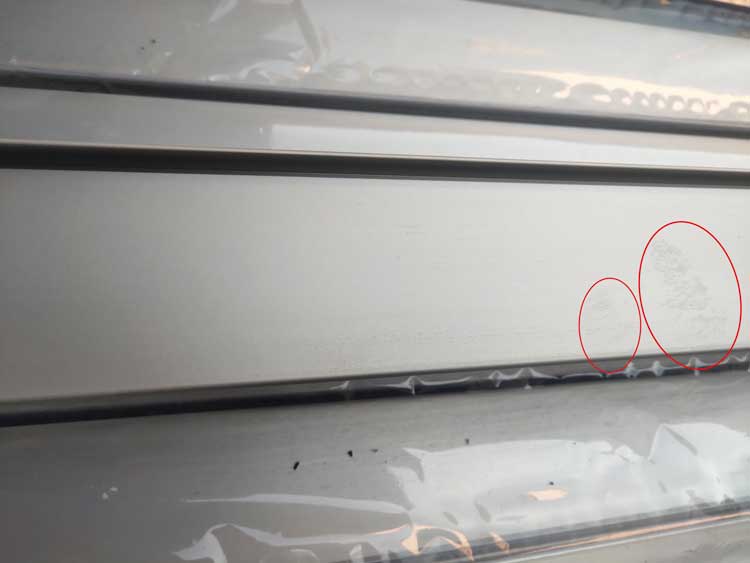

- Spangle like finish, this is supposed to be caused by the impurity of the material. Not all the anodized surface is like this, maybe like 20-30%. However, this much defects will cause the rejection of the whole lot of material.

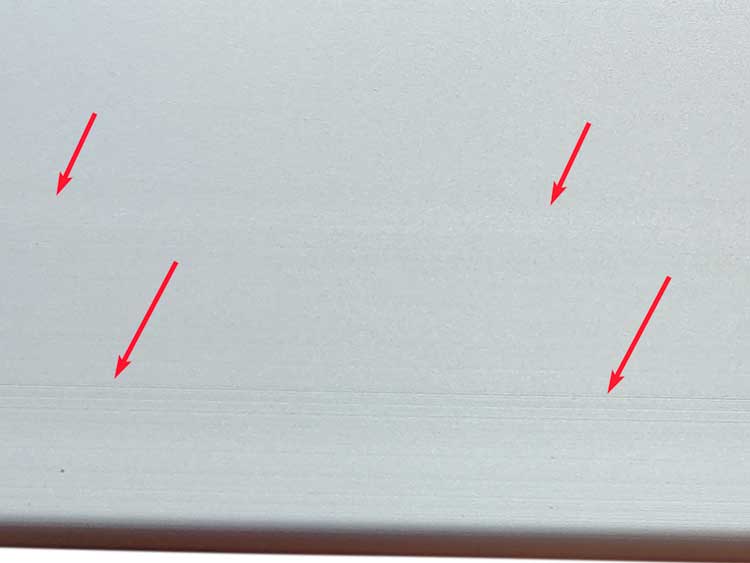

- Mold marks (or tool marks). The mold needs to be maintained regularly in an interval of a certain amount of production, otherwise, the tool marks will start to appear.

The mold marks are quite common on the raw aluminum extrusions. As long as the marks are not too deep, and they can be removed after sand blasting and anodizing, they are acceptable.

Mold marks before anodizing (raw finish)

These mold marks are too deep, they are still visible after sand blasted and anodized.

Mold marks after anodizing

- Poor sealing. You may not detect the poor sealing by eyes, but when you touch it, it has an unpleasant sticky surface. Sometimes we use a marker pen to check the clear anodized parts for sealing.

What makes a qualified aluminum extrusion manufacturer

A committed management team

They will supportive for you quality requirements and replace the defective parts, even when your order volume is low (like 1 to 2 tons).

A concentrated work team

As you can imagine, each process, including the anodizing, loading and unloading, inspection, cutting to lengths and packaging, need a high level of attention. We need concentrated work staff to conduct these processes.

A spacious workplace

The inspection, packaging all need enough work area to be carried out, so it is important to have a spacious workshop.

What we can supply

- We can supply the aluminum extrusions in clear anodize and black anodize. Other colors are also available but the MOQ will be 15 to 20 tons.

- The extrusions are usually 6 meters long, but they can be cut to custom sizes. You only need to pay for the finished pieces, you do not have to pay for the scraps of extra length.

- The extrusions are inspected carefully and then packed in plastic films, papers or carton board.