Aluminum injection molds have long been considered an attractive option for various manufacturing processes, primarily driven by cost considerations and the need for shorter turnaround time.

While aluminum molds are not a new concept and have been used in the past, they haven’t gained widespread popularity in recent years. In this article, we will explore the advantages and disadvantages of aluminum molds to understand why their usage has fluctuated over time.

Table of Contents

ToggleUnderstanding Aluminum Injection Molds

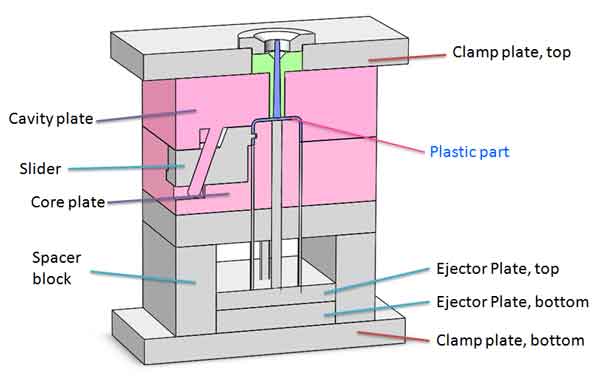

Aluminum injection molds do not signify the complete mold is constructed from aluminum; rather, it means that the mold’s core and cavity are crafted from aluminum, while the mold base remains constructed from steel. This approach offers a valuable advantage in maintaining mold rigidity. The steel mold base provides essential support to the mold core, ensuring structural stability. Simultaneously, the mold core often features intricate shapes, making its fabrication more complex. In contrast, the mold base’s manufacturing process is relatively straightforward, allowing for the retention of necessary mold rigidity while minimizing processing time.

Furthermore, in manufacturing facilities frequently utilizing aluminum molds, the aluminum mold cores may experience shorter lifespans and may need replacement. In such cases, the mold base can be efficiently reused in molds of similar sizes, offering a practical and cost-effective solution.

Advantages of Aluminum Injection Molds

- Cost-Efficiency

Aluminum is relatively affordable when compared to other mold materials. While the price per unit weight may not be the lowest, the cost per unit volume is notably lower than many mold steels. This affordability makes it an attractive choice for manufacturers on a budget.

- Speedy Machining

One of the standout features of aluminum is its exceptional cutting speed. The fast machining capabilities of aluminum significantly reduce processing time. This, in turn, translates to cost savings and shorter production cycles. In fact, aluminum molds can be processed in approximately one-third to one-half the time required for steel molds.

- Rapid Thermal Conductivity

Aluminum boasts impressive thermal conductivity, facilitating efficient heat dissipation. This characteristic helps maintain the optimal mold temperature, preventing issues like slow mold ejection, excessive product shrinkage, and warping due to inconsistent cooling. As a result, aluminum molds are well-suited for applications where precise temperature control is crucial.

Disadvantages of Aluminum Injection Molds

- Limited Surface Finish

One of the key drawbacks of aluminum molds is their inability to be polished to the same degree as steel molds. This limitation can affect the surface quality and dimensional accuracy of the molded parts, making them less suitable for applications where a pristine finish is essential.

- Tool Sticking Issues in Aluminum Machining

When working with aluminum, a common challenge arises: aluminum tends to adhere to the tool, resulting in the formation of built-up burrs. This adhesion issue can significantly impact the machined surface’s smoothness and dimensional accuracy due to alterations in the tool’s size and shape. Consequently, the quality and dimensions of plastic products are compromised as a result.

- Mechanical Limitations

Compared to steel, aluminum has inferior mechanical properties and is less capable of withstanding high-injection speed and high-pressure conditions. This limitation can lead to flashings, even in new molds. Therefore, aluminum molds are best suited for applications involving simple product designs, materials with high fluidity, and lower temperature and pressure requirements. Materials like ABS and PP are well-suited, while materials like PC and glass fiber-reinforced plastics are less compatible due to their higher temperature and pressure demands.

- Welding and Repair Challenges

Aluminum’s poor welding performance and difficulty in polishing make it challenging to repair molds once flaws occur. This can result in increased maintenance costs and downtime.

Choosing the Right Aluminum Grade

When it comes to selecting aluminum for injection molds, it’s important to acknowledge that aluminum’s mechanical properties, including strength, hardness, and rigidity, typically don’t measure up to those of materials like 1045 steel or pricier alloy steels.

Therefore, the preference often leans toward aluminum variants with greater hardness. While aviation-grade aluminum 7075 is a viable option, 6061-T6 is frequently favored due to its considerably more affordable price point.

Cost Savings and Tool Life in Aluminum Injection Molds

How Much Can Aluminum Injection Molds Save?

When considering aluminum injection molds, cost savings can be substantial. While the material itself is less expensive, the primary source of savings lies in reduced processing time. In general, aluminum molds tend to be 20-40% cheaper than their steel counterparts.

Understanding Mold Lifespan

The lifespan of an aluminum injection mold varies depending on factors such as the material being molded and the complexity of the product. For instance, for a product made from PA6+GF30 with a straightforward design, an aluminum mold can typically produce around 2000-3000 shots. When working with materials like PP or ABS, the number of shots can increase to 5000-10000, assuming no unexpected issues arise during production.

However, mold longevity is also influenced by the acceptance of flash, which refers to the presence of excess material at the parting line of the molded product. If strict requirements for flash-free production are in place, it can shorten the mold’s lifespan.

Considering the approximately 30% cost savings offered by aluminum molds, it becomes essential to weigh the pros and cons. While aluminum molds provide significant cost advantages, it’s important to remember that steel molds have a significantly longer lifespan, often lasting hundreds of times longer than their aluminum counterparts. The choice ultimately depends on the specific needs and budget of the project at hand.

Why Ordinary Mold Workers Hesitate to Choose Aluminum Injection Molds

If you were to ask a random plastic molder, you’d often find a reluctance to opt for aluminum injection molds. Several factors contribute to this hesitation:

Unfamiliarity with Aluminum Molds: Many mold workers are not well-versed in the intricacies of aluminum molds. They may lack experience and familiarity with the material, which makes them hesitant to use it.

Challenges During Mold Trial and Production: Aluminum injection molds can pose challenges during mold trials and production runs. Issues like plastic products sticking to the mold or plastic remnants clinging to the sprue’s tail can arise. These problems can lead to mold damage, flash formation, or other production hiccups. Repairing these issues in aluminum molds can be more complex than with steel molds.

Greater Care and Precision Required: Using aluminum molds demands a higher degree of care and precision from production staff. They need to be vigilant and proactive to avoid potential problems. Any accidents or mistakes can result in monetary losses for the company.

Given these challenges, those seeking aluminum molds are often advised to collaborate with specialized manufacturers who have expertise in creating and working with aluminum molds. Despite their advantages, aluminum molds have not gained widespread popularity over the years, emphasizing the importance of finding skilled professionals when choosing this mold type.

Conclusion: Balancing Efficiency and Challenges

In the world of injection molding, choosing between aluminum and steel molds requires a careful evaluation of cost savings and production challenges. While aluminum molds offer affordability and quicker processing, they demand a more cautious approach and have shorter lifespans compared to steel molds. The decision ultimately depends on the specific project requirements, budget considerations, and the willingness to navigate the intricacies of aluminum molds for optimal results.