We are A professional Manufacturer for plastic injection molding in China

Boyan Manufacturing Solutions takes pride in supplying high quality plastic injection molds and injection molded parts, together with professional engineering support and customer services. More importantly, we help you to stay within your budget!

- quality GUARANTEED

- Lower prices

- easy communication

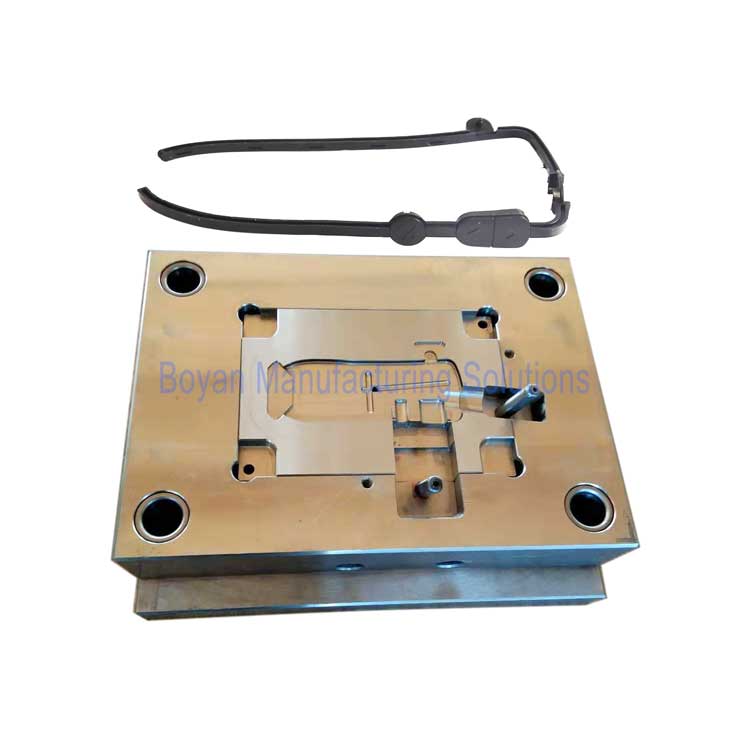

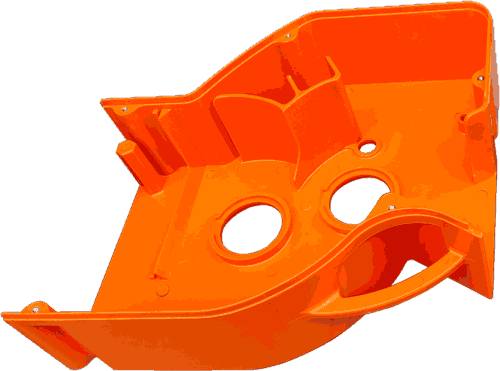

Product Displays

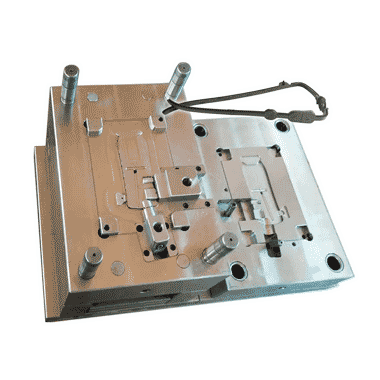

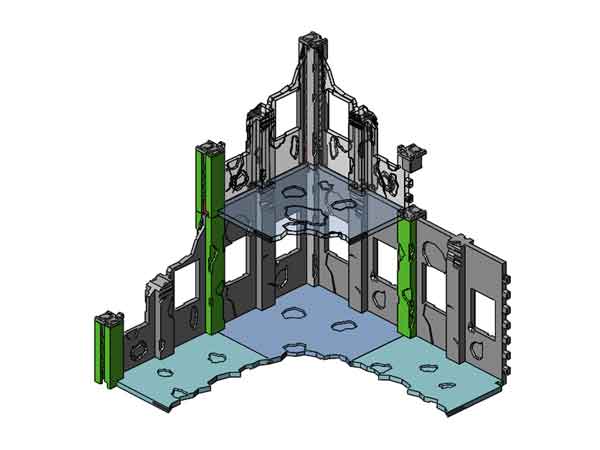

Type: precision molding

This example of the Lego part shows how to achieve the precision of the injection mold final plastic part. Click to see more details.

Type: precision molding

A plastic lens retainer for smartphone cameras, made by 2-shot injection molding with PA6+GF substrate and TPU overmold.. Click to see more.

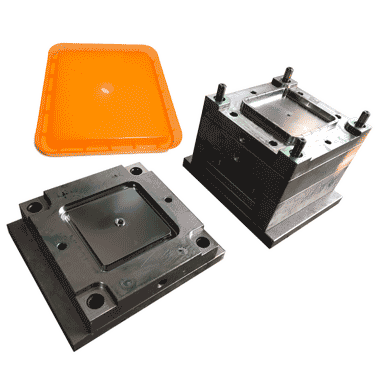

Type: clear plastic molding

These are lenses for LED lights. The surface pattern is most critical for the proper projecting of lights. Each part need to have the same weight for cost saving in large volume production.

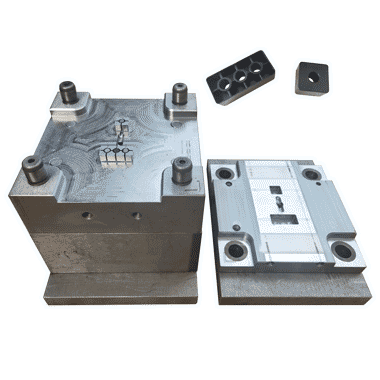

Type: precision molding

This is a pin connector used on PCBs. High precision and uniformity are required.

Type: precision molding / TPU molding

This is a side seal for mobile phones, with the material TPU. There are small details made to high precision to prevent flashes.

Type: TPE overmolding

This is a handle for power tools. The substrate is ABS with TPE overmolded.

Type: chrome plating

This is a wide reflective mirror made of ABS, with the surface plated with chrome.

Type: ultrasonic welding

The cup body consists of 2 walls for better heat insulation. The bottom is welded to the cup body. The material for this cup is ABS.

Ensured quality

Establishing Appropriate Quality Standards for Project Succes

Defining quality standards correctly is a sensitive process, and we will share our expertise in this area to ensure the success of your project.

1. Understand the product

Providing details about the product’s use, how plastic parts are assembled and function in the assembly can help us understand the dimensional and aesthetical requirements.

To meet product requirements, we’ll set inspection criteria for appearance and dimensions, using 3D printed plastic gauges for less precise measurements and CNC machined metal gauges for higher accuracy.

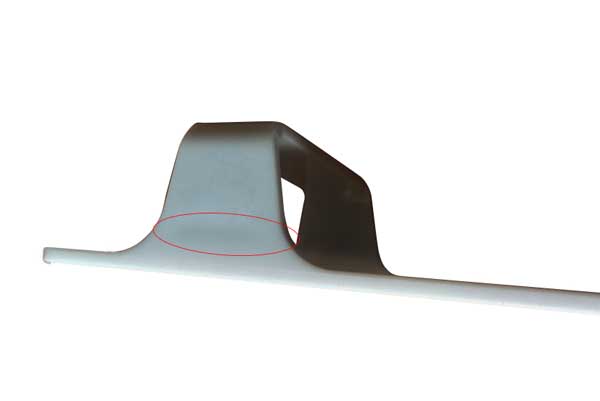

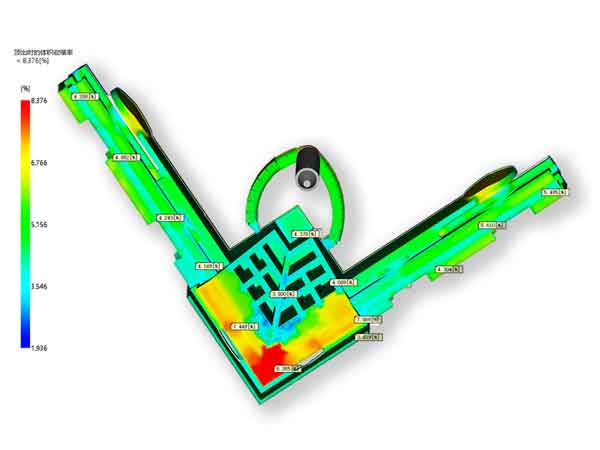

We will conduct a DFM and probably a mold flow analysis to see what issues may arise either on the product side or the mold side. Some issues need attention from the mold design stage.

Many molding defects are predictable, and they can be avoided or kept within an acceptable level.

Our engineering services

Material selection

Choosing the right material is crucial to the success of a project from the very beginning。

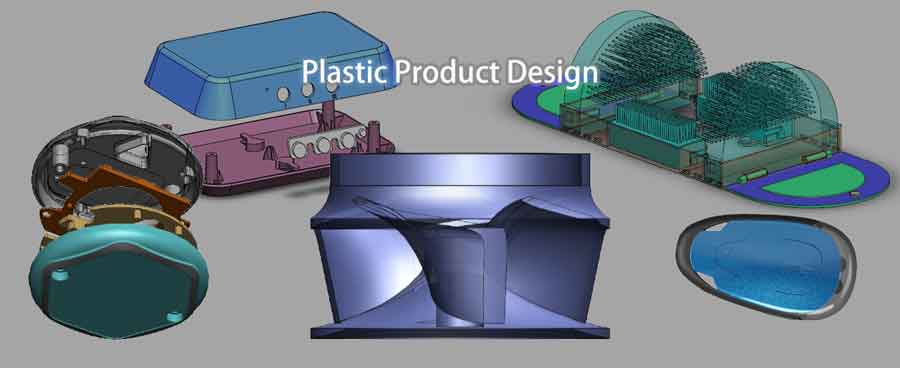

Product design

We don't usually start from scratch, because communication from a distance can be a barrier. We can optimize your design in terms of manufacturability, aestietics, and functionality.

Reverse engineering

In addition to using professional scanning and measuring instruments, it takes experience and talent to replicate a product exactly as the original sample.

Rapid prototyping

Other than photosensitive resins, we can use different materials for rapid prototyping: soft/flexible, transparent, and nylon.

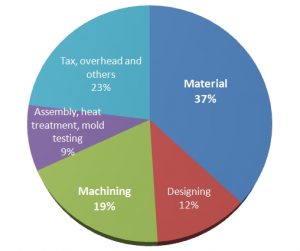

Low prices

At our company, we prioritize affordability and transparency.

Upon your request, we gladly provide a detailed mold cost breakdown, allowing you to observe the precise composition of the expenses.

This way, you can verify that each item has been reasonably and accurately calculated to ensure complete satisfaction.

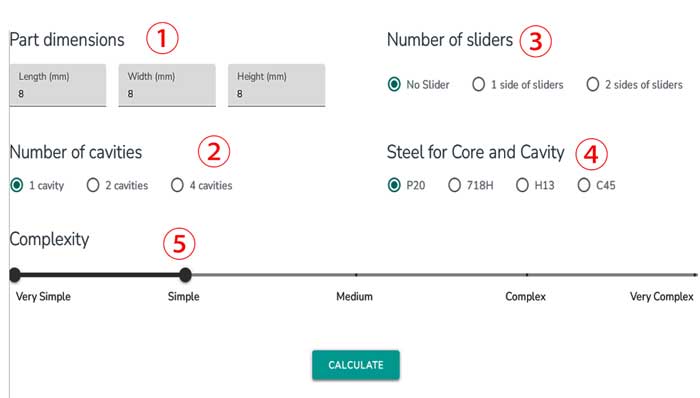

Our online mold cost calculator

Using our state-of-the-art online mold cost calculator, you can obtain an accurate cost estimation for your plastic part within seconds!

Simply enter the ① part dimensions, ② number of cavities, ③ number of sliders, ④ the steel for core and cavity, along with the ⑤ complexity level, and receive a comprehensive price range.

Rest assured, our actual mold quote typically aligns with this estimated range.

Say goodbye to lengthy waiting times and welcome the efficiency of our mold cost calculator!

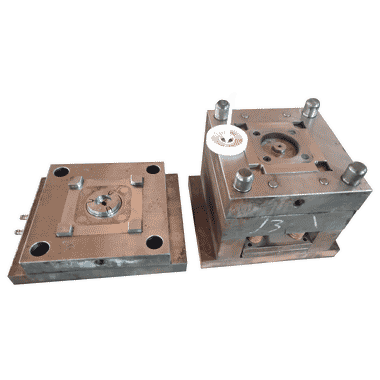

The processes of mold making

The DFM and Mold flow analysis can help you avoid potential production problems, optimize the part and mold design and shorten the overall production cycle.

This will include deciding the type and location of the injection gates and ejector pins, wall thickness and draft analysis, possible molding defects and solutions, and so forth.

- Mold design requires extensive experience, great care, and it is time-consuming.

- The mold design is a key factor in the success of the mold, as the machining is all based on the drawings.

- It is often a collaboration between the molders and designers to ensure that every detail has been properly arranged.

- This process will usually take 2 to 5 days.

- This usually includes CNC milling, wire and electrode EDM (and the machining of electrodes).

- A heat hardening may be required between the rough and finish machining.

- Different grades of processing equipment are available, and choosing the right equipment can save costs while ensuring quality requirements.

- The machining process typically takes 7 to 15 days.

- Ideally, the molded parts should be manufactured to a very high degree of precision so that the mold can be just assembled and put into use. This is possible, but very costly.

- In common practice, the machined parts are usually polished or modified to make sure the ideal engagement of mating components is obtained.

Small errors and omissions in the design should also be fixed. - The mold assembly process will normally take 5 to 15 days.

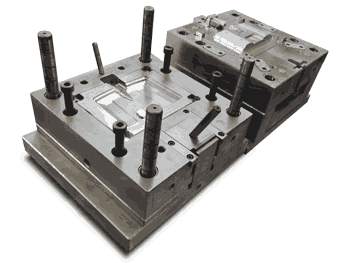

- In this phase, we will check if the mold is working as expected, and verify if the T0 samples meet the dimension tolerances, without noticeable flaws, and function properly in their assembly.

- For T0 samples, the surface texture is usually not yet applied and the tool steel is not yet hardened in anticipation of possible tooling corrections or modifications.

- The cycle time from the very beginning of mold production to T1 samples will usually be 25 to 40 days.

- The mold or the T0 samples may have flaws or imperfections that need to be fixed.

- Sometimes the customer will require design changes on the parts.

- After that, T1 samples will be made for inspection.

- The mold modification will normally take 15 to 30 days.

- After the samples are approved and the mold is tested and ready for production, it is time to apply surface textures and harden the tools.

- Some plastic parts have a polished finish or a sanded finish (which can be simply obtained from electrode EDM), so they do not need the texturing process.

- The hard molds (made of steel H13, S136, etc), the steel is hardened before finishing machining, so they do not need any more hardening at this stage.

Now we are good to move forward to deliver the mold or start production!

Customer testimonials

— At Boyan, we consistently appreciate the chance to embrace challenges, foster creativity, and evolve together with our customers’ enterprises

Customer references are available in these countries. If you would like to speak with our customers directly, we can provide you with their phone numbers.

Frequently Asked Questions

Generally, STEP is the most widely used format, supported by most design software for conversion. Our design tools include UG and SolidWorks.

It’s important to note that we occasionally receive files in STL format. However, STL files are suitable only for 3D printing and cannot be used for mold machining. Converting STL files to STEP format, if requested, will incur additional charges.

Absolutely, but we need detailed information about the product’s use. This includes what the product is, its operating environment such as high/low temperatures, whether it’s used outdoors or indoors, and if it requires resistance to corrosion, flame retardancy. Additionally, we need to know the required mechanical properties like strength and toughness (impact resistance). With this information, we can help select the most suitable plastic material for your project.

Yes, we offer custom color matching based on client requirements. Colors can be customized according to RAL or Pantone codes. However, this method is not perfectly accurate due to slight variations among different color card editions. We have noticed this through our collaborations with many color matching suppliers, thus providing a color sample is more preferable.

There are two methods for color matching: adding color powder or masterbatch at a later stage, or having the color pre-mixed at the raw material factory. The latter requires a larger purchase quantity.

The lead time for injection molding projects varies based on the complexity, precision, and size of the mold. Typically, the production cycle for an injection mold ranges from 25 to 40 days. The initial samples produced using the mold are referred to as T0 samples.

Following the inspection of T0 samples, modifications to the mold may be necessary. This could include design adjustments or corrections to meet the specified dimensions. After modifications, the next set of samples, known as T1 samples, are produced. This cycle can take an additional 15 to 25 days, with additional time for shipping and inspecting the samples, totaling about 30 days.

In summary, the complete process from the start to the completion of a mold generally takes about 2 to 3 months. Sometimes, a second round of modifications is required, although this is less common.

Efficient communication during the sample inspection and problem-solving process is crucial. Without it, the overall timeline may extend further.

If your project with us involves confidential information, it is essential to sign a Non-Disclosure Agreement (NDA) before initiating the collaboration. This ensures that we are aware of the project’s confidential nature and also allows us to enter into similar agreements with our suppliers. In our communications with them, information will be limited to the minimum necessary on a need-to-know basis.

However, understanding the product’s application scenarios helps us ensure its quality, so clients should carefully consider their needs and share useful information with us. This balance allows us to maintain confidentiality while also receiving the context needed to deliver the best possible outcome.

We do not impose restrictions on the MOQ. For some products, the quantity might be as low as 100 pieces. We hope this will lead to more orders in the future, but it’s perfectly fine if it does not.

However, please note that smaller orders may have longer lead times. This is because these orders are typically processed during the intervals of other production schedules, especially when there are specific production conditions required or additional post-processing involved.

To ensure our injection molded products meet specifications, we implement rigorous quality assurance measures. These include material inspections, mold design reviews, precise control of the injection molding process, initial product inspections (FAI), continuous production monitoring, and thorough final quality checks.

Additionally, we actively seek customer feedback for continuous improvement. This comprehensive approach guarantees that our products consistently meet high-quality standards and customer expectations.

For the exported injection molds, we ensure quality through comprehensive measures including mold design review, precision machining and inspection, and mold trial runs. Our approach covers all aspects from raw materials to design, manufacturing, and trial operations to guarantee mold quality. Throughout the mold-making process, we keep our clients updated on progress. Before shipping, we conduct a 4-6 hour trial run to ensure mold quality meets expectations. We encourage clients to communicate any additional requirements before production begins.

Certainly! We provide a comprehensive range of secondary operations and finishing services, including surface treatments such as painting, plating, screen printing, pad printing, and laser etching. Additionally, we offer welding, machining, and assembly services among others to meet the diverse needs of our clients and ensure their projects are completed to the highest standards.

If your project with us involves confidential information, it is essential to sign a Non-Disclosure Agreement (NDA) before initiating the collaboration. This ensures that we are aware of the project’s confidential nature and also allows us to enter into similar agreements with our suppliers. In our communications with them, information will be limited to the minimum necessary on a need-to-know basis.

However, understanding the product’s application scenarios helps us ensure its quality, so clients should carefully consider their needs and share useful information with us. This balance allows us to maintain confidentiality while also receiving the context needed to deliver the best possible outcome.

We specialize more in the production aspect of product design rather than aesthetics, as we are not a professional design firm. While we collaborate with many designers, the initial design phase requires extensive communication with clients and an understanding of their cultural background, which we find challenging. However, we are confident in our ability to design for functionality. You can see an example of our work by clicking on this link.

Absolutely, if requested, we will promptly ship the mold to you, though such situations are rare. Generally, once customers start to have their molds made and kept at our facility for production, it’s uncommon for them to retrieve the molds midway through the process.

Yes, generally speaking, the subsequent maintenance and updates of the molds are our responsibility. This makes sense because if the production profits far exceed the cost of the mold, then we can take responsibility for creating a new mold when its lifespan ends (usually they last 100,000s shot).

However, if the production quantity is very low and there have been no orders for production over 3 years, this may lead to the mold being scrapped or needing repairs, and this is not something we would cover.

For mold costs, we generally require a 50% down payment, with the remaining 50% paid after sample confirmation.

For product production, we usually require a 30% down payment, with the remaining 70% paid before shipment. However, we will carefully inspect the product quality and send the inspection results before shipment.