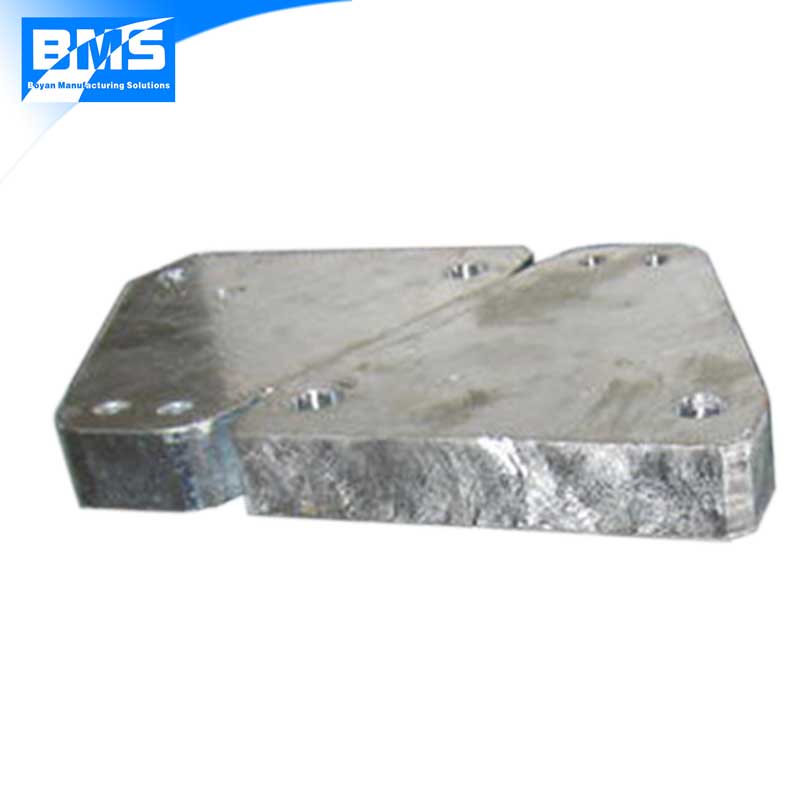

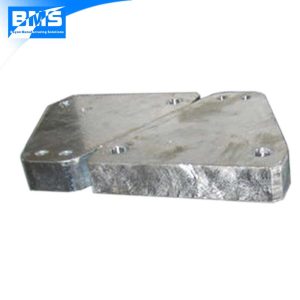

Steel Q345 or S355 machined parts and hot-dip galvanized

These parts are made from Steel Q345, the equivalent of DIN S355. The parts are first machined and then hot-dip galvanized, with the coating thickness 0.07-0.11mm.

Part specification:

| Material | Steel Q345 (S355 DIN) |

| Size (mm) | 280x220x18 |

| Tolerance for key dimension (mm) | 0/-0.05mm |

| Coating: | Hot Dip Galvanized, 0.07-0.11mm |

| Processes | Flame cutting, milling |

Some details:

Directly cut to shape by flame cutting to save costs

We cut the parts by flame cutting directly, and did not do any milling, since this is the most cost-effective method. The appearance is still acceptable after galvanizing. Our customer is okay if the appearance is not so perfect on the edges, and it does not cause any functional issues, so this production method is the best among other possible methods.

These are the raw material:

Flame cut and holes drilled:

The holes are reamed after galvanizing to meet the tolerance

The tolerance for the holes is 0.05mm, so we have to ream the holes after galvanizing, because the coating thickness is 0.07-0.11mm, which makes it impossible to meet the tolerance without a secondly machining after the galvanizing process.