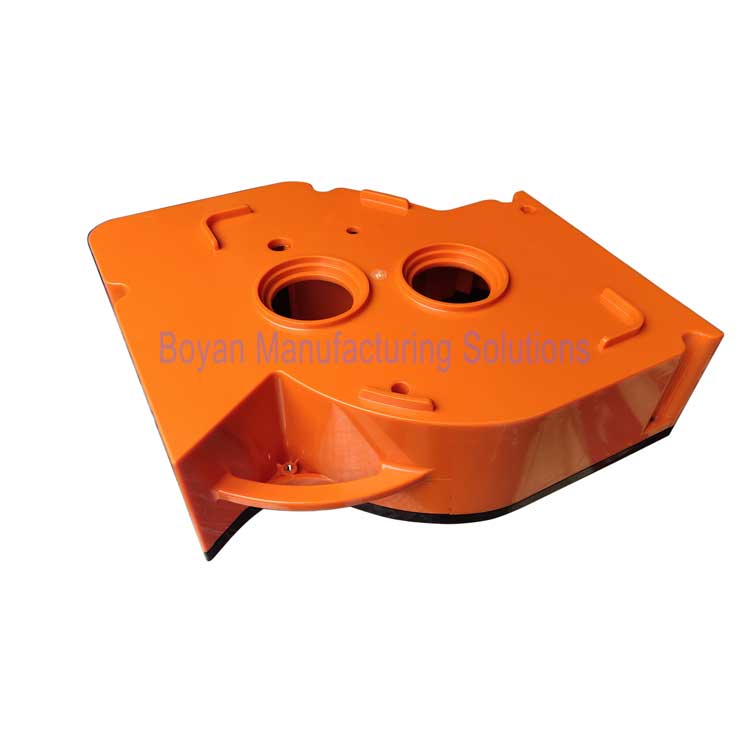

A custom plastic enclosure for home appliance

This is a large custom plastic enclosure used for a home appliance. It consists of 2 pieces: the top and the base. The material is ABS.

Part specifications

| Material | ABS |

| Size | 40*38*11.5 cm (16*15*4.6 inches) |

| Weight (for the top and the base) | 1.5 kg (3.3 pounds) |

| Tolerance for the key dimension | +/-0.8mm (+/-0.03 inch) |

| Processes | Injection molding |

Mold price

- For the top piece: $12,500

- For the base piece: $8,000

- Cavity number: 1 for each mold

- Mold material: P20

- Lead time: 60 days

Now let’s see what are the critical quality requirements for this product:

Precise control on dimensions

As you can see these 2 parts of this custom plastic enclosure are matched together by inserting into a groove, and due to the large size of these 2 parts, the span of the groove is quite large. This means we need to meet the tight tolerance, which is +/-0.8mm.

Mold price

- For the top piece: $12,500

- For the base piece: $8,000

- Cavity number: 1 for each mold

- Mold material: P20

- Lead time: 60 days

Now let’s see what are the critical quality requirements for this product:

Precise control on dimensions

As you can see these 2 parts of this custom plastic enclosure are matched together by inserting into a groove, and due to the large size of these 2 parts, the span of the groove is quite large. This means we need to meet the tight tolerance, which is +/-0.8mm.

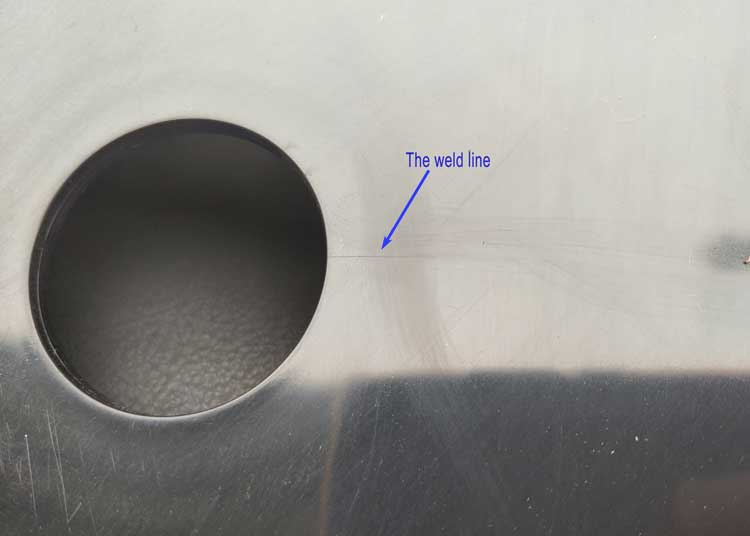

Avoid weld lines

Many custom plastic enclosures require a pleasing appearance. Since there are many holes on the parts, it is easy to have weld lines around the holes. Besides, the base is black color, this will make the weld lines more visible. In order to minimize the weld lines, we heated the mold temperature to over 80℃, by doing so, the weld lines can only be seen when you look it very closely.

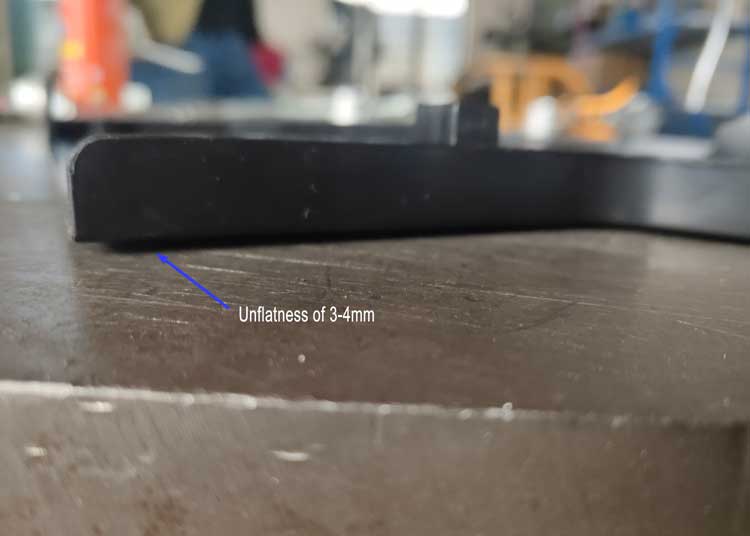

Control the flatness

It is critical to control the flatness of flat plastic pieces. We have checked the flatness of the base part, it is about 3-4mm. Certainly, this is within an acceptable range, since the parts will be flattened when they are tightened by screws.

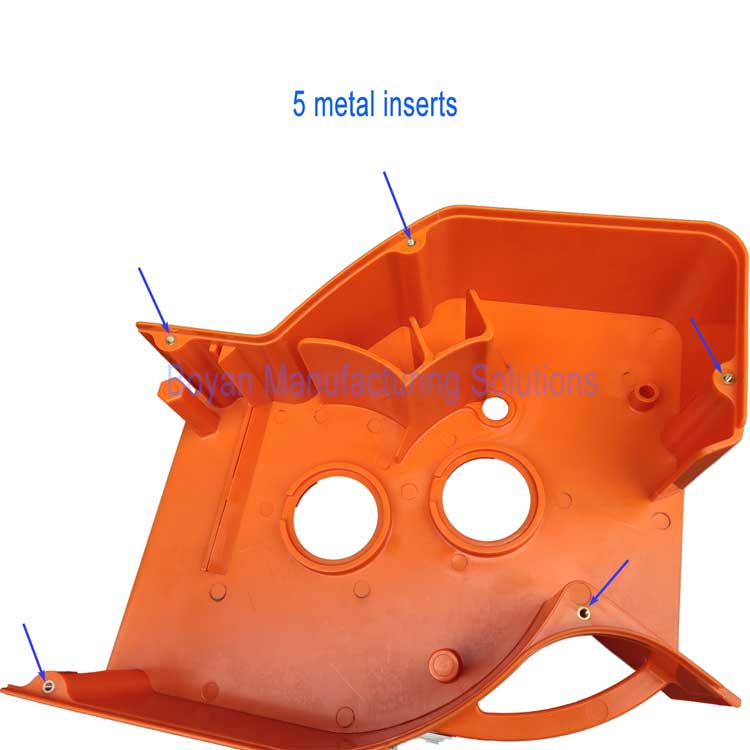

Insert molding with 5 metal inserts

There are 5 pieces of threaded brass inserts molded into the top pieces. Please look at the pictures below: