Custom Laser Tube Cutting Service with Rotational Laser Head

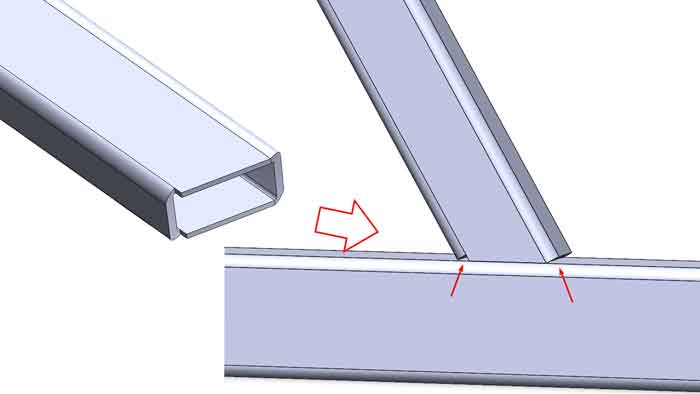

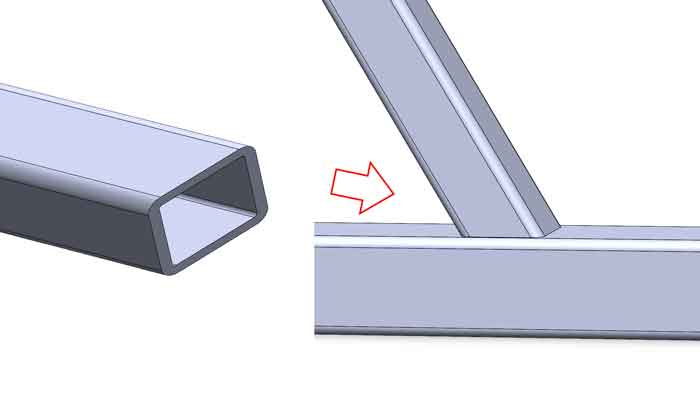

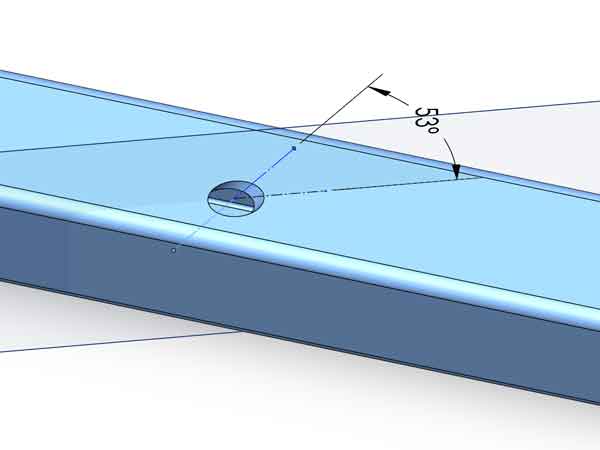

We have extensive experience in metal tube processing, utilizing both fixed and rotational laser head cutting machines. Our expertise covers various materials, cutting geometries, and processing techniques, ensuring optimal manufacturability. Additionally, we focus on maintaining cost efficiency while delivering high-quality results.