The Importance of Understanding the Flame Retardant Plastics

When selecting flame-retardant plastics, gaining some knowledge about the subject is crucial.

Initially, deciding on the Flammability rating is fundamental, and this choice is often straightforward. However, the type of plastic flame retardant, an aspect frequently overlooked, is equally important.

Flame retardants play a decisive role in enhancing the fire resistance of plastics, effectively preventing or slowing down the spread of flames. Choosing the right flame retardant is not just a matter of safety; it also involves environmental protection and cost-effectiveness. Different types of flame retardants work through various mechanisms.

Classification of Plastic Flame Retardants

Broadly speaking, flame retardants are classified into two types: halogenated and non-halogenated.

Understanding Halogen Elements

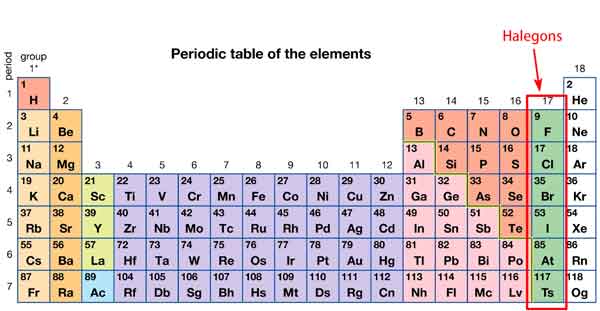

First, let’s delve into what halogen elements are. Halogens are the elements in the seventh main group of the periodic table, including fluorine (F), chlorine (Cl), bromine (Br), iodine (I), and astatine (At).

These elements share a common characteristic: seven electrons in their outermost electron shell, making them highly reactive and easily forming compounds with other elements.

Halogens typically exist as negative ions, like the chlorine (Cl) ion in sodium chloride (NaCl). They exhibit strong electrophilicity and oxidizing properties in chemical reactions. Widely present in nature in various forms, from saltwater to minerals, halogens are used in a range of applications, including disinfection, pharmaceutical manufacturing, and plastic processing. Due to their reactivity, halogens have raised environmental and health concerns.

It’s important to note that in flame retardants, the halogen elements predominantly used are bromine (Br) and chlorine (Cl), with bromine being more common.

What are Halogenated Flame Retardants?

Halogenated flame retardants are chemical substances that contain halogen elements (such as bromine [Br] and chlorine [Cl]) and are used to enhance the fire resistance of materials. During combustion, these retardants disrupt the chemical reaction chain of flames by releasing halogen free radicals. Halogenated flame retardants primarily include the following categories:

Brominated Flame Retardants:

- The most common and widely used halogenated flame retardants.

- Include substances like Tetrabromobisphenol A (TBBPA), Decabromodiphenyl Ether (Deca-BDE), and Hexabromocyclododecane (HBCD).

- Applicable to various plastics, electronic devices, textiles, and more.

Chlorinated Flame Retardants:

- Include Chlorinated Paraffins, Chlorinated Polyethylene, and others.

- These retardants are commonly used in PVC and other chlorinated polymers.

Bromine-Chlorine Based Flame Retardants:

- Compounds combining both bromine and chlorine elements.

- Examples include brominated chlorinated alkanes, brominated chlorinated benzenes, etc.

- These composite retardants utilize the synergistic effects of bromine and chlorine to enhance flame retardancy.

Combination of Brominated Compounds with Other Additives:

- To increase efficiency and reduce costs, brominated flame retardants are often used in conjunction with synergists like Antimony Trioxide (Sb2O3).

- This combination enhances the overall flame retardancy of the material.

What are Non-Halogenated Flame Retardants?

Non-halogenated flame retardants are a class of compounds that do not contain halogen elements (such as chlorine [Cl] and bromine [Br]) in their chemical composition. These retardants are generally considered more environmentally friendly because they do not release halogen compounds during combustion, which could be harmful to both the environment and human health. The main types of non-halogenated flame retardants include:

Phosphorus-based Flame Retardants:

- These retardants work by forming a char layer during combustion, isolating the material from oxygen and thereby inhibiting flame spread.

- Common phosphorus-based retardants include red phosphorus, ammonium phosphate, and phosphates.

- Suitable for various plastics, fibers, coatings, and rubbers.

Nitrogen-based Flame Retardants:

- These retardants typically function by releasing non-combustible gases or promoting the formation of a stable char layer through chemical reactions.

- Common nitrogen-based retardants include melamine, urea-formaldehyde resins, etc.

- Frequently used in foam plastics, fibers, and coatings.

Inorganic Flame Retardants:

- Including aluminum hydroxide, magnesium hydroxide, etc., these substances absorb a significant amount of heat and release water vapor when heated, thus reducing the material’s temperature and slowing flame spread.

- Widely applied in plastics, rubbers, and coatings.

Non-halogenated Organic Flame Retardants:

- This category includes various organic compounds, such as expandable graphite and epoxy-based compounds.

- They chemically react during combustion to form an expanded char layer, providing flame retardancy.

Nanotechnology-based Flame Retardants:

- Utilizing nanotechnology, these retardants involve adding minute nanoparticles to materials to enhance their flame resistance.

- These nanoparticles can be inorganic, like nano-oxides, or organic-inorganic hybrid materials.

The choice of non-halogenated flame retardants depends on the type of material requiring flame retardancy, processing conditions, end-product application requirements, and considerations of environmental and health impacts. With increasingly stringent environmental regulations and higher market demands for safety, non-halogenated flame retardant technology is rapidly evolving.

Comparing their Advantages and Disadvantages

Halogenated and non-halogenated flame retardants each have their strengths and weaknesses in terms of flame retardancy, environmental impact, and application scope.

Halogenated Flame Retardants

- Advantages

- Typically, they offer high flame retardancy efficiency, quickly interrupting flame spread, especially in electronics and electrical products.

- They are cost-effective, stable, require low addition levels, compatible with synthetic resins, and maintain the original physical and chemical properties of the products.

- Disadvantages

- The main concerns are environmental and health-related. These retardants may release toxic halogenated gases and other harmful substances during combustion, causing environmental pollution and potentially affecting human health over time. Hence, their use is restricted or banned in many countries and regions.

Non-Halogenated Flame Retardants

- Advantages

- Environmentally friendly. They do not produce toxic halogenated gases when burned, making them a safer, more sustainable choice. Non-halogenated retardants, such as phosphorus and nitrogen-based ones, are often used in applications with higher environmental requirements.

- Disadvantages

- Their flame retardancy efficiency might not be as high as that of halogenated retardants, and they can be more costly.

Therefore, when choosing a flame retardant, it’s necessary to comprehensively consider factors like flame retardancy effectiveness, environmental impact, and cost to find the most suitable solution.

Guide to Choosing the Right Flame Retardant Nylon

Recently, when procuring flame retardant nylon, we discovered that suppliers generally offer three main options: halogenated flame retardant nylon (usually brominated), non-halogenated flame retardant nylon, and red phosphorus flame retardant nylon. Among these, halogenated and non-halogenated flame retardant nylons are more commonly used, while red phosphorus flame retardant nylon is relatively less common.

Different colors of these materials

Firstly, these different types of flame retardant nylon are distinguishable by their colors. Halogenated flame retardant nylon appears light yellow, whereas non-halogenated flame retardant nylon leans more towards white, resembling nylon with white pigment added. Besides, both these types can be processed into black or other dark colors. On the other hand, red phosphorus flame retardant nylon is primarily available in black and brown.

Burning characteristics

Another method to identify these materials is by lightly burning them with a lighter. Halogenated flame retardant nylon will produce black smoke and a strong irritating smell upon burning, while non-halogenated flame retardant nylon emits less white smoke and has a less intense odor.

Further details require extra effort and may not always be essential.

Gaining a deeper understanding of the specific components of flame retardants might require extra effort. Most manufacturers may not readily provide detailed information, as there are actually only a few types of flame retardants on the market, but they are simplified into these three categories for ease of remembrance and selection. These flame retardants are usually made in granular form, similar in appearance to regular plastic pellets.

In summary, when choosing flame retardant nylon, considering its color, burning characteristics, and application scenarios is crucial. This not only relates to the performance of the product but also concerns the safety in subsequent processing and use. Therefore, clarifying needs and thoroughly communicating with suppliers to select the most suitable type of flame retardant nylon for your project is essential.