Overview — Plastic Speaker Cover

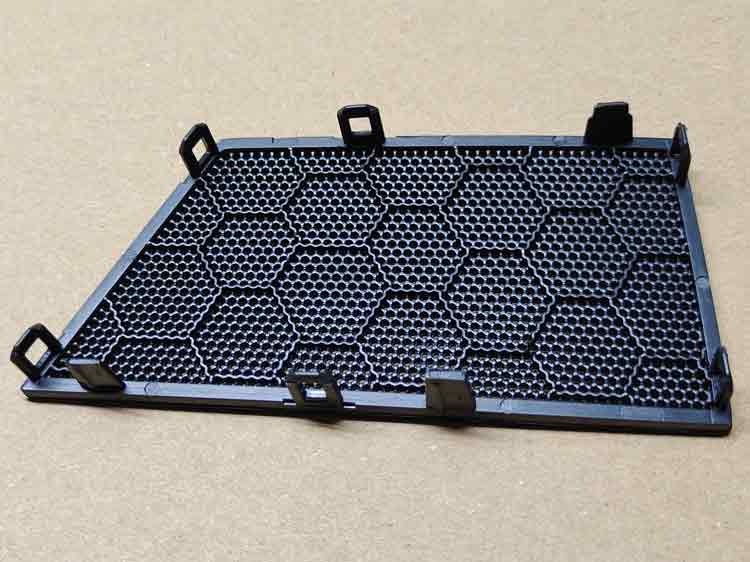

Plastic speaker covers are protective covers with many small holes or mesh patterns. They protect the speaker from dust and damage while allowing sound to pass through clearly. At the same time, they also add a stylish look to the speaker.

These covers can be made in various shapes, such as round, oval, or more complex designs. Because of their perforated structure, they require high-precision molds and advanced production techniques.

Here, we will focus on introducing one featured cover in detail, along with a few other designs. This will help you quickly understand the key features of our products and see our strong manufacturing capabilities.

Product information

| Item | Details |

|---|---|

| Product dimension | OD 128 * Height 26 mm |

| Materiaal | PP |

| Mold information | 2 cavities, cold runner |

| Gate type | Submarine gate |

| Tolerance for key dimensions | ±0.15mm |

| Surface finish | VDI15-18 |

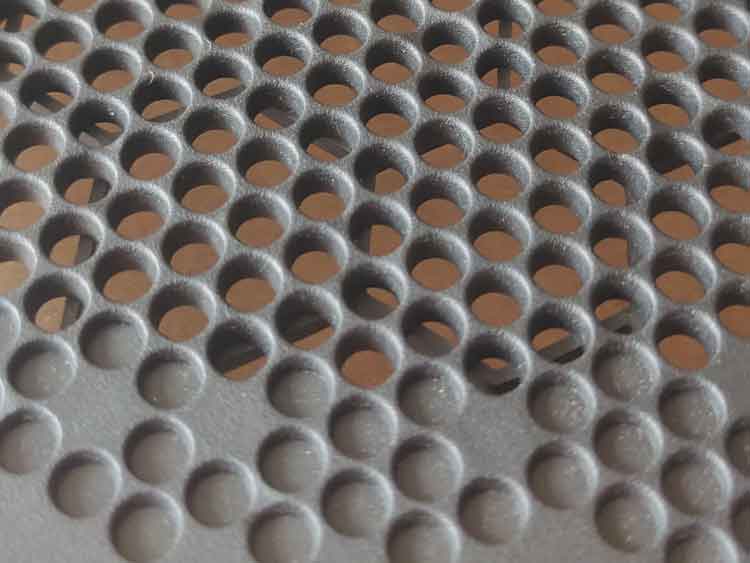

Surface Quality and Detail Requirements

The surface of the plastic speaker cover must be smooth and free from any small defects, especially because of the many small holes. Each hole on the front side has a slight rounded edge, giving the product a cleaner and more refined appearance.

The back side does not have these rounded edges.

In addition, the product is very sensitive to injection molding defects. Issues such as gate blush, weld lines, silver streaks, flash, and warping are not acceptable.

The Material — PP

Plastic speaker covers are usually made from PP, ABS, or PC/ABS. This particular product uses PP, which helps reduce weld lines and other appearance-related molding defects. However, PP has lower gloss and is softer compared to ABS or PC/ABS.

Gate Design – submarine gate

Because the product has high appearance requirements, side gates are not suitable since they can leave visible marks along the edge, even after trimming. We usually use a submarine gate to avoid surface scars. However, it’s important to control gate blush on the outer surface, which is more challenging with ABS and PC/ABS but less of an issue with PP.

Avoiding Warpage

Because the many holes reduce the product’s rigidity, warpage can occur during injection molding. To prevent this, careful analysis of gate number and placement is needed.

In this case, the warpage is well controlled. The slight bending seen in photos is due to the product’s intended 3D curved shape, not an actual defect.

Minor bends can also be corrected during assembly, as the part is flexible and can fit closely to the mating surface.

Using a Mold Temperature Controller

To achieve better surface quality and avoid defects such as weld lines and silver streaks, we use a mold temperature controller during injection molding, even when using PP material.

Preventing Sticking to the Mold

Because the mesh holes are mostly in the upper mold and the lower mold has fewer ribs, it is important to prevent the part from sticking to the upper mold during ejection. This is mainly achieved by designing appropriate draft angles.

Ejection Design — Ejector Pins + Ejector Plate

Most plastic speaker covers use a combination of ejector pins and an ejector plate. Ejector pins cannot be used in the mesh areas, and in this product, the pins are very small (around 0.5 mm), making them hardly visible in photos.

Venting: Role of Ejector Pins

The ejector pins not only push the part out but also help with venting. Because the cover has many holes, the filling process is complex, and air can get trapped near the edges or in the center areas. These gaps around the ejector pins provide ventilation channels.

Other Plastic Speaker Covers

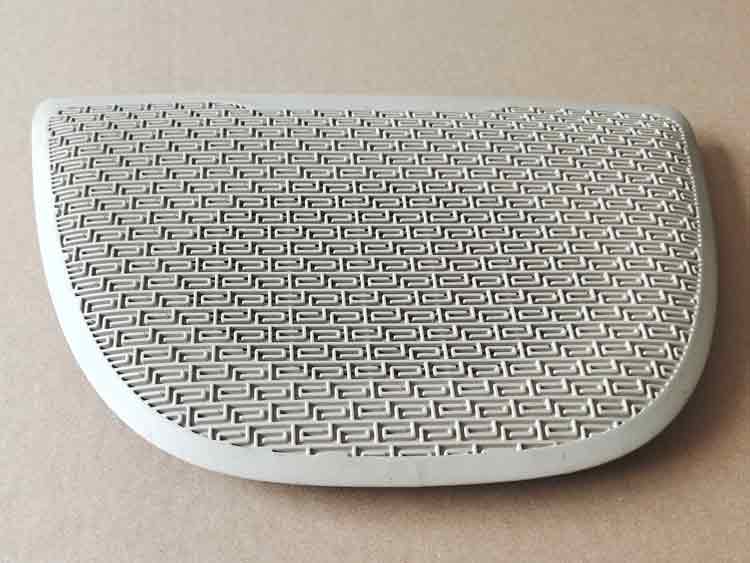

Mesh-Type Speaker Cover

More Unique Appearance, Higher Cost

Mesh-type covers offer a more distinctive look but require longer and more expensive mold processing compared to simple perforated designs.

Avoiding Mold Rib Damage

The thin mold ribs used for mesh designs (only 0.4–0.5 mm) are fragile and easily damaged during production. Any damage requires time-consuming repair, including re-polishing and reapplying the surface texture, which significantly increases cost and effort.

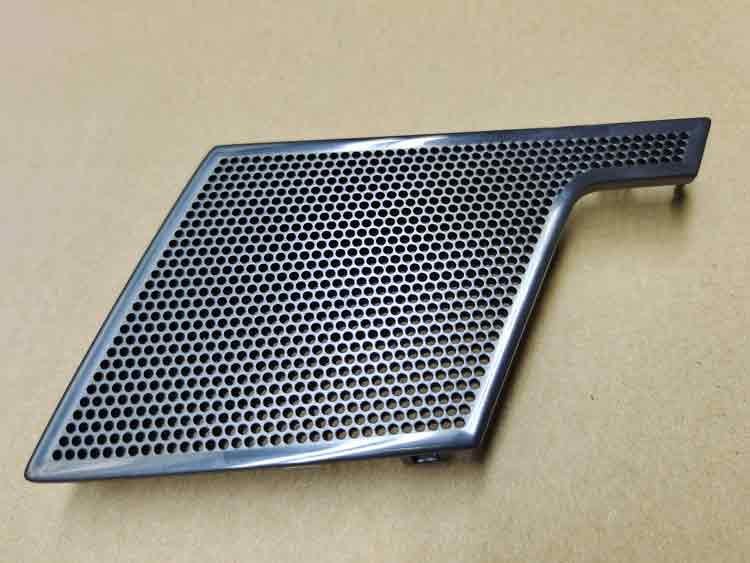

ABS Speaker Cover — Product 1

Higher Gloss, Greater Hardness, and Higher Cost

Compared to PP, ABS offers higher gloss and greater hardness, making it suitable for different applications. However, it also has higher production costs and is more prone to surface defects during molding.

Ejection: Ejector Pins and Ejector Plate

This product uses larger ejector pins, so the pin marks are more visible. The mesh area in the center is ejected using an ejector plate.

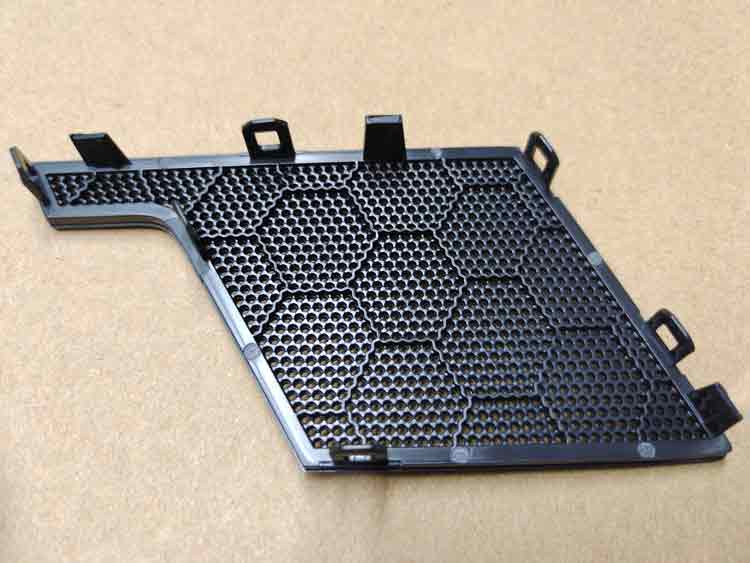

ABS Speaker Cover — Product 2

Complex and Versatile Shapes

This product has an irregular shape, showing that speaker covers can be made in various forms to meet different installation needs.

Samenvatting

Plastic speaker covers play a crucial role in both protecting speakers and contributing to their visual integration within different environments. Careful material selection, precise mold design, and controlled manufacturing processes are essential to achieving reliable performance and appearance.