A custom nylon gear with thick walls

This is a nylon gear with the material of PA66 GF30. Nylon has great strength, ductility, and wear-resistance, but the problem is it absorbs moisture, which will cause it to “swell”. However, this particular application does not require a high accuracy of dimensions, the more important thing is longer product life and reliability. That is why nylon is chosen for this gear.

Boyan is capable of designing and manufacturing all kinds of plastic gears.

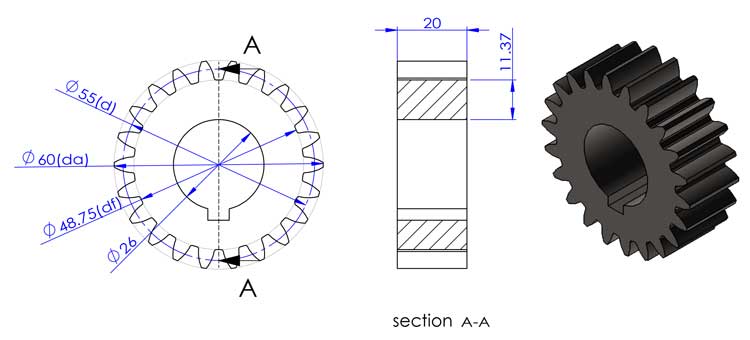

Main gear parameters

| Module (m) | m=2.5mm |

| Nombre de dents (z) | z=22 |

| Teeth width | 20mm |

| Diamètre de référence (d) | d=55mm |

| Diamètre de la pointe (da) | da=60mm |

| Root diameter (df) | df=48.75mm |

Mold cost: $2,200

- Cavity number: 2

- Matériau du moule : 718H

- Délai d'exécution : 35 jours

The thick-wall structure is the main challenge

For any plastic material, thick-wall designs are always to be avoided because it may cause uneven contraction, sink marks, vacuum voids, and other injection molding flaws, and many of these flaws will cause dimensional instability, which is not good for gears.

The wall thickness for this nylon gear is 11.37mm, which is shown on the above drawing. This is pretty thick for injection molding.

How do we minimize the flaws

If you look at the pictures closely, you will see all the flaws are controlled within an acceptable level. The surfaces are quite smooth and flat, we do not see noticeable discontinuity on the surface.

We have taken the following measures to ensure a good quality of this nylon gear:

- Optimize the mold design, which allows filling the material quickly and evenly. We have conducted mold flow analysis before the mold design was finalized

- Higher injection pressure and holding pressure.

- Longer holding time.

- Quick cooling of the parts after they have been ejected.