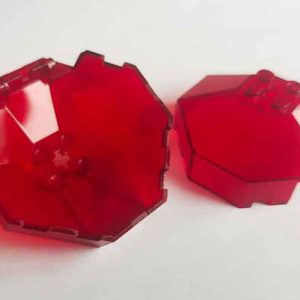

Pomo de ajuste de plástico con serigrafía rotativa

This product is a plastic adjustment knob (also called a plastic control knob) designed with precision molding and high-quality surface finishing. Its outer surface features recessed textures for better grip and appearance, while the scale markings are applied using rotary screen printing for sharp and durable results.

Product information

| Artículo | Details |

|---|---|

| Product dimension | Ø50 × 28 mm |

| Material | PA6 GF20 |

| Net Weight | Approx. 16 grams |

| Mold information | 2 cavity, 4 sliders, cold runner |

| Tolerance for key dimensions | ±0.10mm |

| Roundness | 0.15mm |

Design Features

-

Recessed outer texture improves both appearance and handling comfort. This requires a mold with four sliders, limiting the tool to two cavities.

-

Dimensional accuracy: General to high level, with tolerances of ±0.10 mm and roundness within 0.15 mm.

-

Surface finish: Fine sand texture with strict appearance requirements. No weld lines, gate blush, or gloss inconsistencies are allowed.

Alternatively, PMMA (Acrylic) is another excellent transparent material with better scratch resistance. However, it is more prone to cracking in stress concentration areas, and thus, it is not recommended when screws are used for fastening.

Rotary Screen Printing

-

Inner thread for positioning: The knob’s inner surface has intermittent threads that lock with raised bosses on the positioning shaft, ensuring accurate circumferential alignment during printing.

Fit Precision and Its Impact: The fit between the knob and the positioning shaft must be carefully controlled. If the fit is too loose, it can cause blurred printing; if it’s too tight, the knob may be difficult to fit onto the positioning shaft, reducing production efficiency.

-

Printing alignment: The markings are not random. Each printed number corresponds to a specific inner groove, enabling precise orientation.

-

Gear-rack synchronization: The positioning shaft is coaxial with a gear driven by a rack, which moves with the screen mesh. This guarantees that the knob rotates in perfect sync with the mesh.

-

Importance of fit: The bosses and threads must engage tightly, minimizing clearance. Any play could cause slipping, resulting in blurred or distorted printing.

Watch our video to see the rotary screen printing process in action.

Boyan Soluciones de fabricación specializes in high-quality injection molding and custom plastic parts. With extensive experience and a focus on precision, we deliver reliable, cost-effective solutions for various industries.

If you need injection molded parts or custom manufacturing solutions, contact us today. We’re here to help bring your projects to life!