Custom Multi-Material Plastic Toy with Silicone and Metal Part

Este custom pl

astic toy demonstrates multi-material manufacturing by combining plastic injection-molded parts, compression-molded silicone, and stainless steel stamped components in one compact toy assembly.

Each material and process serves a unique role — plastic for structure, silicone for flexibility and touch, and metal for electrical and mechanical function.

At Boyan MFG, we specialize in custom toy production y multi-material toy assembly, offering full OEM/ODM manufacturing services from tooling to final assembly.

Información sobre el producto

| Artículo | Detalles |

|---|---|

| Dimensión del producto | Ø38 × 9 mm |

| Material | ABS, PC, Silicone, Stainless steel |

| Peso neto | Approx. 23 grams |

| Información sobre el moho | 2 cavity, 4 sliders, cold runner |

| Tolerancia de las dimensiones clave | ±0,10 mm |

| Roundness | 0.15mm |

Key Features

-

Multi-material construction: plastic + silicone + metal

-

Precision plastic toy molding service using injection molding

-

Silicone toy parts manufacturer capability for flexible and soft-touch elements

-

Metal stamping toy components for structure and strength

-

Full plastic toy assembly service under one roof

-

Custom color, texture, and packaging options

-

Available for OEM & ODM toy projects

Plastic Injection-Molded Components

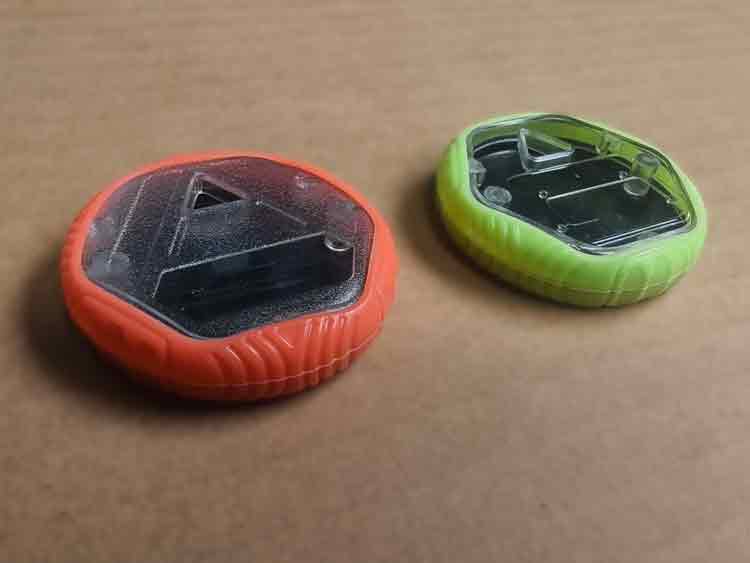

This toy includes five plastic parts made by injection molding — one transparent piece and four black components. Each piece serves a specific structural or functional purpose in the final assembly.

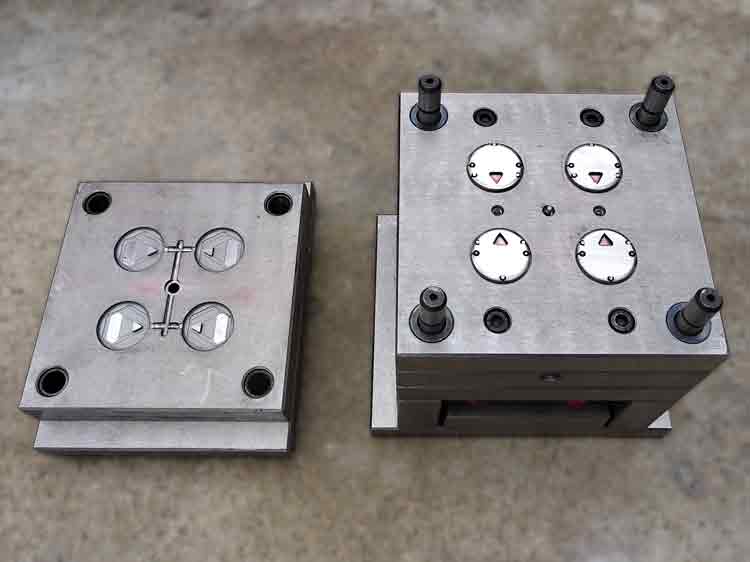

Mold Configuration

To reduce tooling costs, we used three sets of molds for all five parts.

-

-

En transparent cover uses a four-cavity mold.

Four-cavity injection mold for the transparent cover of the custom plastic toy — using edge gates for stable production and balanced flow. Injection-molded transparent covers for the custom plastic toy, connected by the sprue from the four-cavity edge-gated mold. -

En other four components are produced using two family molds, each with a 2 + 2 cavity layout.

-

-

This arrangement was carefully chosen to balance part geometry, size, and molding feasibility. When too many parts share a single family mold, maintaining consistent injection quality can become challenging — especially for parts with different wall thicknesses and flow requirements.

Diseño de puertas for the Outer Shell

For both the cover and the base, we selected an edge gate design, which offers simplicity and stable molding performance.

An edge gate, however, leaves a small gate mark on the surface. Fortunately, this mark is completely covered by the silicone sleeve on the final product, so it does not affect appearance.

If the silicone cover were not present, we would make the gate thinner or relocate it to make the mark less visible.

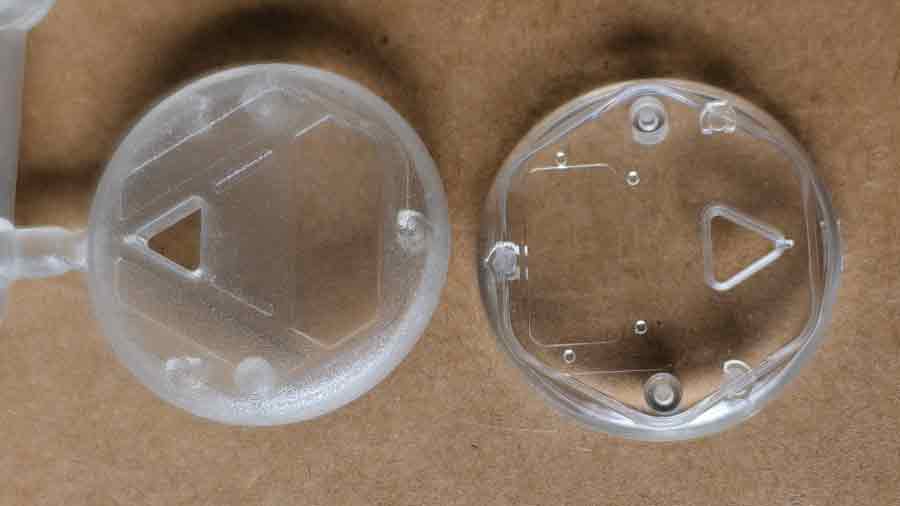

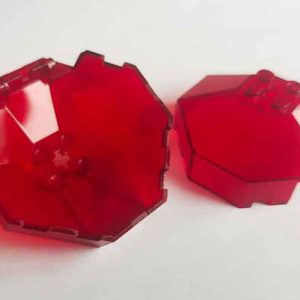

Surface Finish of the Transparent Cover

The transparent top has a textured surface (VDI 27–30). Because transparent plastics are sensitive to visual defects such as gate blush, silver streaks, and flow lines, surface treatment must be done carefully.

For the T0 sample, we kept the surface polished to make any molding defects clearly visible during inspection. After confirming the quality, we applied the final texture in the next sampling stage (T1, T2 and etc.).

You can see the difference between the polished y textured versions in the comparison images.

Quality Considerations

To ensure both aesthetics and function, several quality points were prioritized:

-

-

Appearance:

The transparent cover requires a flawless look, while the black base also demands high visual quality due to its glossy finish. Glossy black parts are particularly sensitive to surface defects. -

Surface Flatness:

Surface flatness directly impacts perceived quality. Poor polishing or uneven tooling can cause light reflection distortions, making the product appear less refined. -

Dimensional Accuracy:

Since the internal structure houses a PCB board and other electronic components, the tolerance requirement of ±0.10 – 0.15 mm is sufficient — not extremely tight but critical for smooth assembly.

-

Silicone Components – Compression Molded

Mold Setup and Process

Compression molding is ideal for silicone parts because tooling costs are low, though it requires more manual labor during production.

When a mold has a larger number of cavities, both the tooling cost and production cost per part become more economical.

The photo below shows one of the silicone molds used for this product.

Controlling Flash During Compression Molding

In compression molding, flash—the thin layer of excess silicone that seeps between mold plates—is a common concern, especially for small, detailed parts.

Because this component is compact and features fine surface details, it must be manually removed from the silicone sheet after molding.

To keep flash to a minimum, the mold surfaces must be precisely machined and aligned.

A small parting line gap is maintained so that only a very thin layer of silicone escapes, which can then be easily torn off during deflashing.

Although a slight trace of flash can still be seen along the edges, it remains well within the acceptable tolerance for this process and does not affect the appearance or performance of the part.

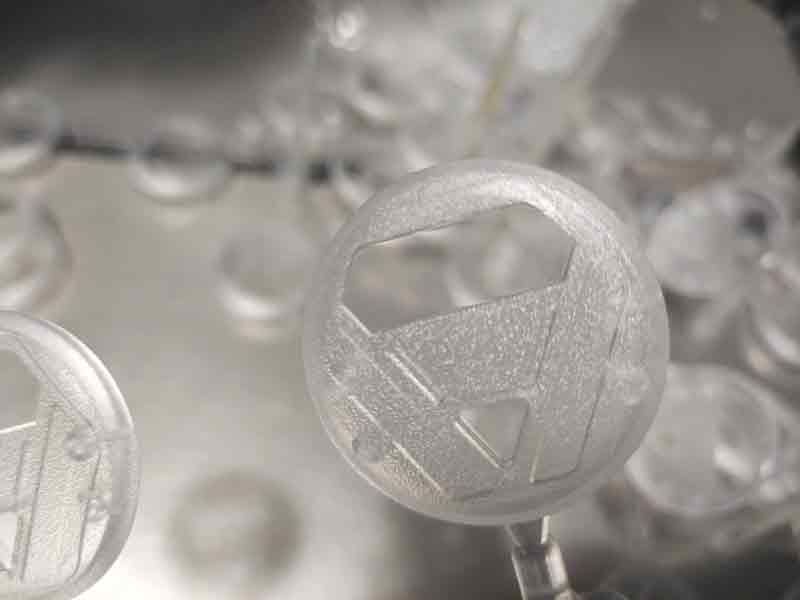

Complex 3D Geometry

As you can see, the silicone ring wraps around the outer surface of the product and features a complex three-dimensional pattern, similar to a tire tread.

The image below shows the corresponding texture inside the mold, illustrating how these fine tread patterns are formed during the molding process.

This requires careful mold design and precise machining, as each part must be manually demolded one by one after compression molding.

Despite the added complexity, this process ensures excellent fit and a high-quality surface.

Color Matching and Visual Evaluation

Color was matched according to the Pantone codes provided by the client.

We even prepared two different shades within the same color family for the customer to choose from.

Photos were taken using specific lighting and angles to highlight the subtle color differences.

While we can also ship physical samples for evaluation, photographs are often a faster and more efficient way to communicate visual results.

Stainless Steel Stamped Components

These two stamped parts are used as battery electrodes. They are small, precise, and made of stainless steel with a nickel-plated surface for better conductivity and corrosion protection.

Our process ensures high-quality finishing and consistent performance for even the tiniest components.

Material and Surface Treatment

The parts are made from high-strength stainless steel, which provides both durability and resistance to oxidation.

A thin layer of nickel plating enhances electrical conductivity and surface appearance, making it suitable for electronic toy applications.

Fine Details and Tight Tolerances

Each component includes tiny semi-circular slots y bent sections, which require precise forming and edge control.

We use high-precision dies and controlled stamping pressure to achieve clean edges, smooth bends, and consistent dimensions across all cavities.

Capability for Small and Large Runs

Whether the order quantity is small-batch prototyping o large-scale production, Boyan MFG can handle it efficiently.

Our custom metal stamping service supports a wide range of parts — from toy connectors to miniature brackets — with stable quality and quick turnaround.

Conclusión

This project highlights Boyan MFG’s strength in multi-material toy manufacturing, combining moldeo por inyección de plástico, silicone compression molding, and estampación metálica into a single, well-coordinated process.

By integrating different materials and production methods, we deliver custom toy solutions that are both visually refined and functionally reliable — from concept design to full OEM production.